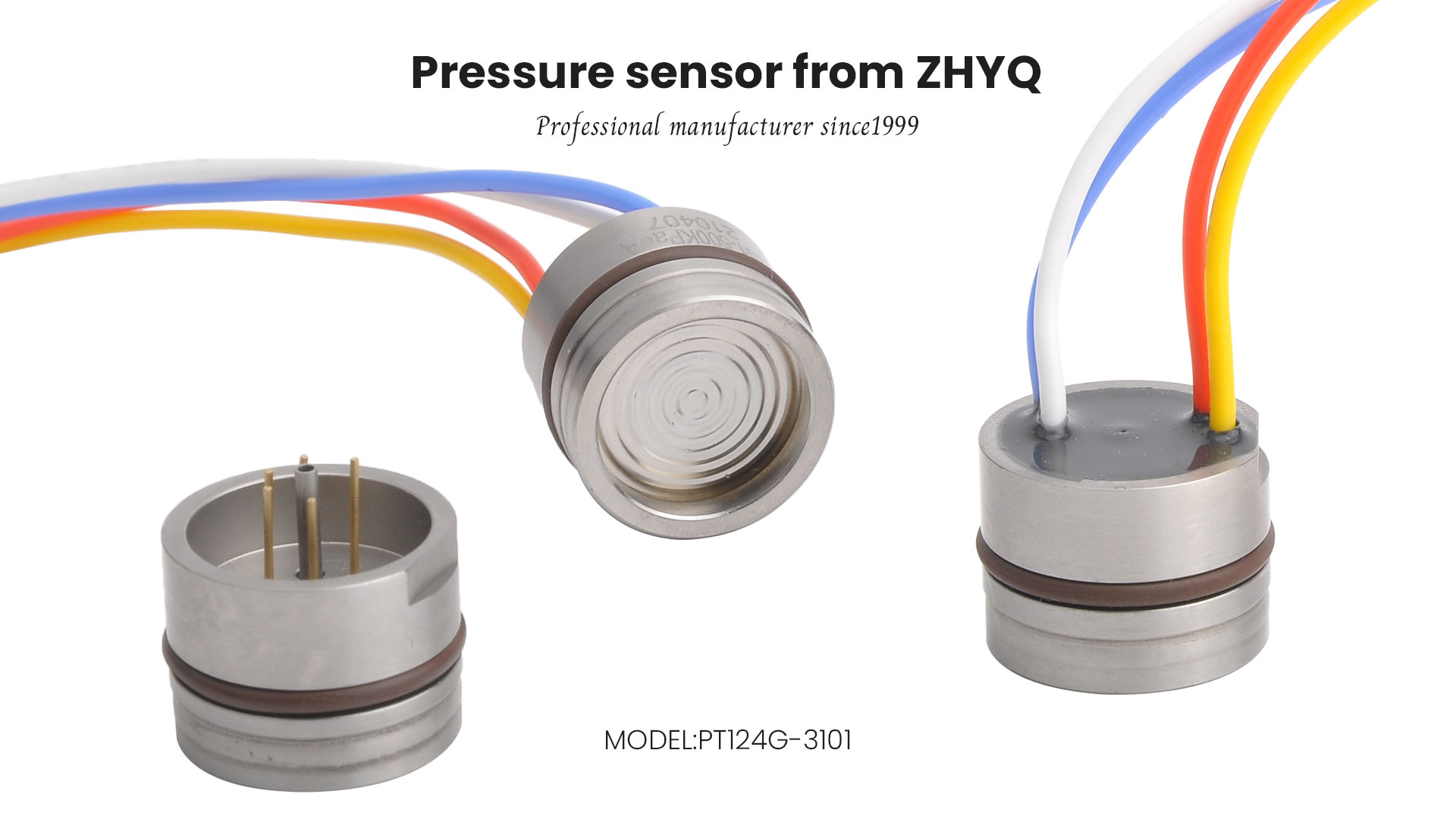

- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2025-02-07

- Zhyq

- 118

Inline process refractometers can play an important role in many aspects of industrial wastewater treatment!

1.Pretreatment stage

1.1. Water quality monitoring: Inline process refractometer can monitor the initial pollutant concentration of wastewater in real time, such as chemical oxygen demand (COD), biochemical oxygen demand (BOD), ammonia nitrogen, total phosphorus and other indicators, to help staff understand the degree of pollution of wastewater and provide a basis for the selection of subsequent treatment processes and parameter adjustment.

1.2. Acid-base adjustment: The pH value of industrial wastewater has an important impact on the subsequent treatment effect. The online pH concentration meter can monitor the pH value of wastewater in real time, so as to add acid-base regulator in time and adjust the pH value of wastewater to a suitable range, creating good conditions for subsequent treatment.

1.3.Grease detection: For oily wastewater, the online oil concentration meter can monitor the content of grease in wastewater. It is installed in front of pretreatment equipment such as grease traps, which can timely grasp the changes in grease concentration, judge the grease separation effect, and adjust the operating parameters of the grease separation equipment or take other oil removal measures when necessary.

2. Biochemical treatment link

2.1. Nutrient control: In the biochemical treatment process, the growth of microorganisms requires an appropriate amount of nutrients such as carbon source, nitrogen source, phosphorus source, etc. Inline process refractometer can monitor the concentration of these nutrients in wastewater, adjust the amount of nutrients added in time according to the needs of microorganisms, ensure the normal growth and metabolism of microorganisms, and improve the biochemical treatment effect.

2.2. Dissolved oxygen monitoring: Dissolved oxygen (DO) concentration is a key factor affecting the activity and treatment effect of aerobic microorganisms. The online dissolved oxygen concentration meter can monitor the dissolved oxygen content in the biochemical reaction tank in real time. The staff can adjust the operating parameters of the aeration equipment accordingly to ensure that the dissolved oxygen concentration in the tank is appropriate and provide a good living environment for aerobic microorganisms.

2.3. Sludge concentration monitoring: The activated sludge method is a common biochemical treatment process, and the sludge concentration is crucial to the treatment effect. The online sludge concentration meter can monitor the concentration of sludge in the aeration tank in real time, help the staff control the sludge discharge and return ratio, maintain the sludge concentration within a suitable range, and ensure the stable operation of the biochemical treatment system.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *