- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2024-03-01

- Zhyq

- 185

Piezoelectric Effect of Pressure Sensor

Pressure sensor is a type of sensor commonly used in industrial practice, and the pressure sensor we usually use is mainly manufactured using the piezoelectric effect. Such sensors are also called piezoelectric sensors.

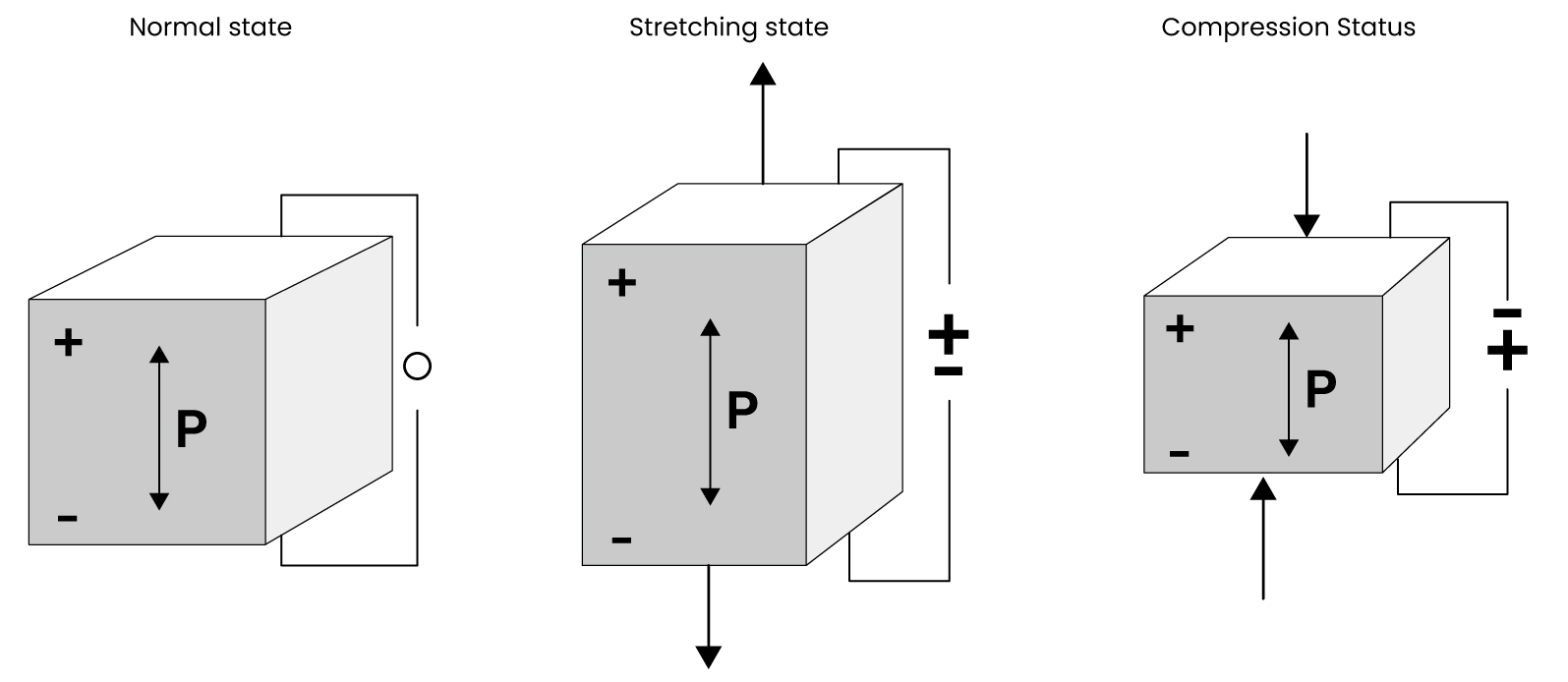

We know that crystals are anisotropic and amorphous is isotropic. When some crystal media are deformed by mechanical force in a certain direction, a polarization effect is produced; when the mechanical force is removed, they will return to an uncharged state, that is, when they are under pressure, a certain crystal medium will Some crystals may produce an electrical effect, which is the so-called polarization effect. Scientists developed pressure sensors based on this effect.

The main piezoelectric materials used in piezoelectric sensors include quartz, potassium sodium tartrate and ammonium dihydrogen phosphate. Among them, quartz (silicon dioxide) is a natural crystal. The piezoelectric effect is found in this crystal. Within a certain temperature range, the piezoelectric properties always exist, but after the temperature exceeds this range, the piezoelectric properties are completely lost. disappears (this high temperature is the so-called “Curie point”). Since the electric field changes slightly with stress (that is, the piezoelectric coefficient is relatively low), quartz is gradually replaced by other piezoelectric crystals. Potassium sodium tartrate has great piezoelectric sensitivity and piezoelectric coefficient, but it can only be used in environments with room temperature and low humidity. Ammonium dihydrogen phosphate is an artificial crystal that can withstand high temperatures and relatively high humidity, so it has been widely used. Nowadays, the piezoelectric effect is also applied to polycrystals, such as current piezoelectric ceramics, including barium titanate piezoelectric ceramics, PZT, niobate piezoelectric ceramics, lead magnesium niobate piezoelectric ceramics, etc.

The piezoelectric effect is the main working principle of piezoelectric sensors. Piezoelectric sensors cannot be used for static measurements because the charge after external force is only preserved when the loop has infinite input impedance. The actual situation is not like this, so this determines that the piezoelectric sensor can only measure dynamic stress.

Piezoelectric sensors are mainly used in the measurement of acceleration, pressure and force. Piezoelectric acceleration sensor is a commonly used accelerometer. It has excellent features such as simple structure, small size, light weight and long service life. Piezoelectric acceleration sensors have been widely used in vibration and shock measurement of aircraft, automobiles, ships, bridges and buildings. In particular, the shape of piezoelectric sensors has a special status in the aviation and aerospace fields. Piezoelectric sensors can also be used to measure combustion pressure and vacuum inside the engine. It can also be used in the military industry, for example, it can be used to measure the changes in chamber pressure and the shock wave pressure at the muzzle at the moment when a gun is fired in the chamber. It can be used to measure both large pressure and small pressure.

Piezoelectric sensors are also widely used in biomedical measurements. For example, ventricular catheter microphones are made of piezoelectric sensors. Because measuring dynamic pressure is so common, piezoelectric sensors are widely used.

In addition to piezoelectric sensors, there are also piezoresistive sensors manufactured using the piezoresistive effect, strain gauge sensors using the strain effect, etc. These different pressure sensors use different effects and different materials, and can be used in different situations. Unique uses.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *