- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2020-08-27

- Zhyq

- 90

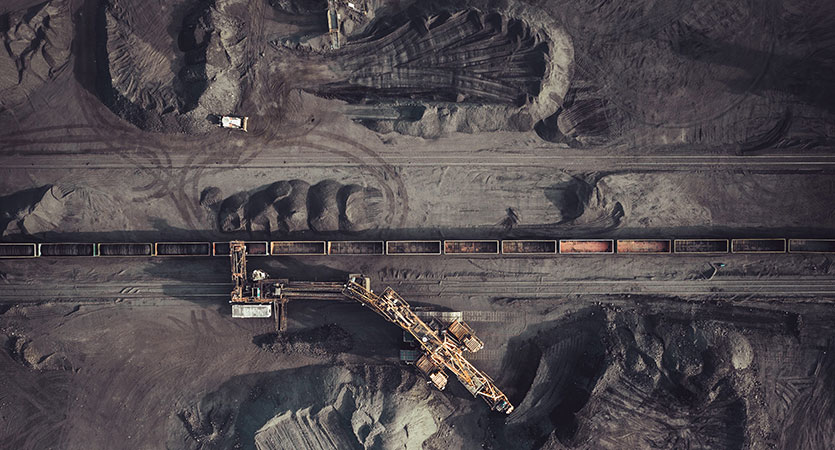

Why pressure measurement sensors are a mines most important device?

As one of the most heavily used pieces of equipment in any mining or tunnelling operation, effective pressure measurement sensors for mines are an essential device across the industry.

Pressure measurement sensors are used for a range of applications, including measuring the level of material in a tank and how much liquid or air pressure has built within a pipe.

When measuring a material, the pressure sensor is placed on the bottom of the tank to measure the head pressure or the weight of that liquid on to the sensors diaphragm, which will tell the operator how much liquid is in the vessel.

Where a site has liquid moving around a facility, a pressure transmitter will monitor the pressure of the liquid being transferred. If the pressure gets too high, it’s possible that the pump is over-pressurising, which could result a costly burst pipe.

According to John Leadbetter, managing director of leading mining equipment provider Vega: “These devices are used widely across the mining industry. They might have different applications at different sites, but pressure transmitters would be one of the most frequently used instruments on a mine site.

“Operators must ensure that that there’s a pressure that’s able to push the liquid around, and secondly that they don’t exceed the pressure of the pipe, in case they have a blockage or a closed valve.”

Essential equipment for a range of applications

ZHYQ offers two types of pressure measurement sensors: process pressure devices and differential pressure devices. While the former measures the pressure of the air or liquid, differential equipment measures two pressures to calculate the difference between the two, for example, across a filter to check the pressure going in and coming out to determine whether the filter needs cleaning. Should the reading show a bigger pressure difference between incoming and outgoing, it’s likely that the filter has become blocked.

In underground mining operations, air is pumped underground for essential ventilation and circulation. If a differential pressure appears across the filters, this tells personnel that the require cleaning before they become inefficient and a safety risk to employees.

Another essential application for pressure measurement sensors is in the water boring process. Water is very rare in most mining areas so operators have to sink deep bores into the ground to draw their water from.

We offer this application very successfully, providing a pressure transmitter that is lowered into these bores and informing staff how much liquid is available. If they have a series of bores around the mine site, they can chop and change where they’re drawing their water from depending on how much water is available in each location.

Water has to be used in the mining process and the most expensive mistake an operator can make is boring where there is no water because they will destroy their pumps.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *