- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2023-08-04

- Zhyq

- 38

Application of Online Viscometer in Spray Drying of Milk Powder

Online viscometer improves the efficiency of spray drying process in milk powder production

Application

Powdered milk, also known as dried milk, is a dairy product that is made by dehydrating liquid milk through several drying processes until it is a powder.

Dried milk can be used for various applications, such as:

- Recombination of milk and milk products

- In the bakery industry to increase the volume of bread and improve its water-binding capacity. The bread will then remain fresh for a longer period of time

- Substitute for eggs in bread and pastries

- Producing milk chocolate in the chocolate industry

- Producing sausages and various types of ready-cooked meals in the food industry and catering trade

- In baby foods: baby milk powder

- Production of ice cream

- Animal feed, calf growth accelerator

- Baked goods, snacks and soups

- Cheese milk extension (powder is added to local fresh milk to increase the yield of cheese)

- Dairy desserts

- Direct consumer use (home reconstitution)

- Infant formulae

- Nutritional products for invalids, athletes, hospital use etc.

- Recombined “fresh”, UHT, evaporated and sweetened condensed milks

- Recombined cheeses, mainly “soft” or “fresh”

- Recombined coffee and whipping creams

- Recombined yoghurts and other fermented products

Dried milk is a manufactured dairy product made by evaporating milk to a dry material. One purpose of drying milk is to preserve it; milk powder has a far longer shelf life than liquid milk and does not need to be refrigerated, due to its low moisture content. Another purpose is to reduce its bulk for economy of transportation. Powdered milk and dairy products include such items as dry whole milk, non-fat dry milk, dry buttermilk, dry whey products and dry dairy blends. Each field of application makes its own specific demands of milk powder.

Milk powder manufacture includes many heating procedures, which consume a lot of energy. The present manufacturing process has been greatly optimised during the last few decades. The adoption of new milk powder technologies will be critical. Upstream and downstream process units will be influenced by the optimization of single process units. As a result, it is critical to consider the entire manufacturing chain. Engineers’ objective is to create an optimization routine that considers energy and water usage, Lifecycle assessment (LCA), and economic elements, resulting in a sustainable milk powder manufacturing chain.

Value of viscosity measurements in spray drying step of milk powder manufacturing

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, slurry or liquid. This process is often used as a final production step before selling or packaging products. A source of heat and a medium to remove the vapour produced by the process are often involved. In bio-products like food, grains, and pharmaceuticals, the solvent to be removed is almost invariably water.

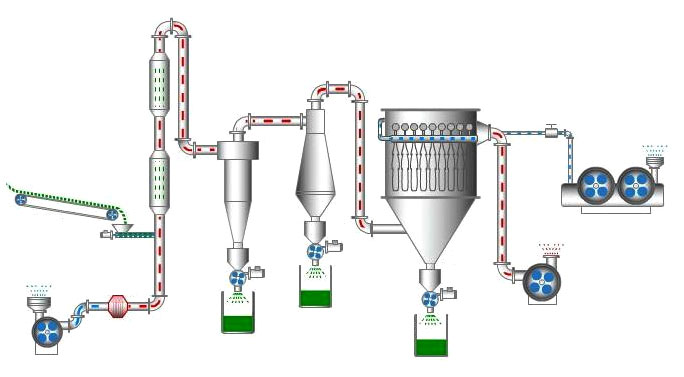

This process is widely used in the food and chemicals industries for making products as diverse as baby foods, coffee, soup mixes and dyestuffs. The efficiency of drying is largely determined by the degree of atomisation, which is directly proportional to the viscosity of the feed solution. Control of milk concentrate viscosity and total solids (TS) content prior to spray drying can improve dairy ingredient manufacture.

Thus, the viscosity of the milk at the atomisation step has a crucial effect on the characteristics of the resulting milk powder. Installed at the pre-atomiser point, a viscometer offers significantly better control of the atomisation process, leading to reductions in wastage, lower energy consumption and better control of product texture, bulk density and moisture content.

Consequences of inadequate viscosity management during spray drying

It is often because of the recipe complexity, the development time, and the costs of development that spray-drying in powder form is inefficient. Viscosity parameter failure during spray drying affects production efficiency in various ways, including:

- End product quality is unstable: consistency problems, ingredient variations, poor dry extract

- Moisture content not according to specifications

- Loss of nutritional value

- Less or bad taste

- Riveted batches

- Short shelf life

- Inefficiencies in the production process: loss of productivity and profits

- Waste of energy: drying towers use a lot of energy and increase overhead costs

Viscosity measurements of concentrated milk are challenging due to its non-Newtonian properties, suspended solids and gases, heavy processing (pressure, vibration, contamination) and cleaning procedures.

Challenges

Because of its non-Newtonian flow properties, age-thickening characteristics, and the presence of suspended solids and gases, measuring the viscosity of concentrated milk is a difficult task. Exposure to hostile process conditions, such as plant vibrations, fouling, cleaning agents, dust, and so on, presents additional challenges in the design of on-line probes in food processing plants.

Many laboratory viscometers currently available have limitations, i.e., measurements are time-consuming, not suitable for rapid real-time monitoring of concentrate viscosity and may not be suitable for characterising samples with complex rheological properties (e.g., materials which are time, temperature and shear dependent). Research with rotational-type viscometers showed that the latter have some limitations in a dairy processing context which partly explains their poor uptake in milk powder plants. Some limitations of conventional viscometers can be overcome by inline viscosity measurements that monitors concentrate viscosity in real-time for improved process control.

Requirements from an inline process monitoring equipment

The ideal PAT (Process Analytical Technologies) tool is an inline instrument that can monitor and measure process parameters simultaneously in real time while operating in a highly automated environment. Instruments must be of sanitary design, operate robustly within the full process cycle (production and cleaning). Inline determination of the rheological properties of moving fluids (i.e. dairy concentrates) is one of the process parameters where PAT tools can be add real value in terms of optimising process control. Measurement of process viscosity is crucial in the monitoring and control of a variety of concentration processes in the dairy industry. Continuous monitoring of the rheological behaviour of the fluid can allow for optimisation of the process e.g. pumping (avoid pump blockage and failure), evaporation (limit fouling and maximise water removal) and spray drying (avoidance of nozzle fouling).

To guarantee that any measurement acquired is representative, the optimum design should allow for cleaning-in-place with little fouling, rapid reaction time, and good sample renewal or even better, if there are no sampling needs. A probe must meet sanitary regulations, such as the elimination of dead spots where germs could multiply. Because certain atomisation systems use high-pressure nozzles, the optimal viscosity measuring technique may be determined by the atomisation type.

Studies have revealed that torsional vibration gave the most trouble-free performance of those systems evaluated for monitoring viscosity. Its advantages include high immunity to plant vibration, ease of cleaning and low maintenance requirement, having no moving parts.

Importantly, measurements are unaffected by changes in flow rate or the presence of suspended solids or gases. Installed at the pre-atomiser point, the viscometer offered significantly better control of the atomisation process, leading to reductions in wastage, lower energy consumption and better control of product texture, bulk density and moisture content. Inline viscosity monitoring of powdered milk improves manufacturing by optimizing the homogeneity of dehydrated milk, creating consistent reconstituted products, increasing yields and reducing losses.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *