- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2025-05-07

- Zhyq

- 22

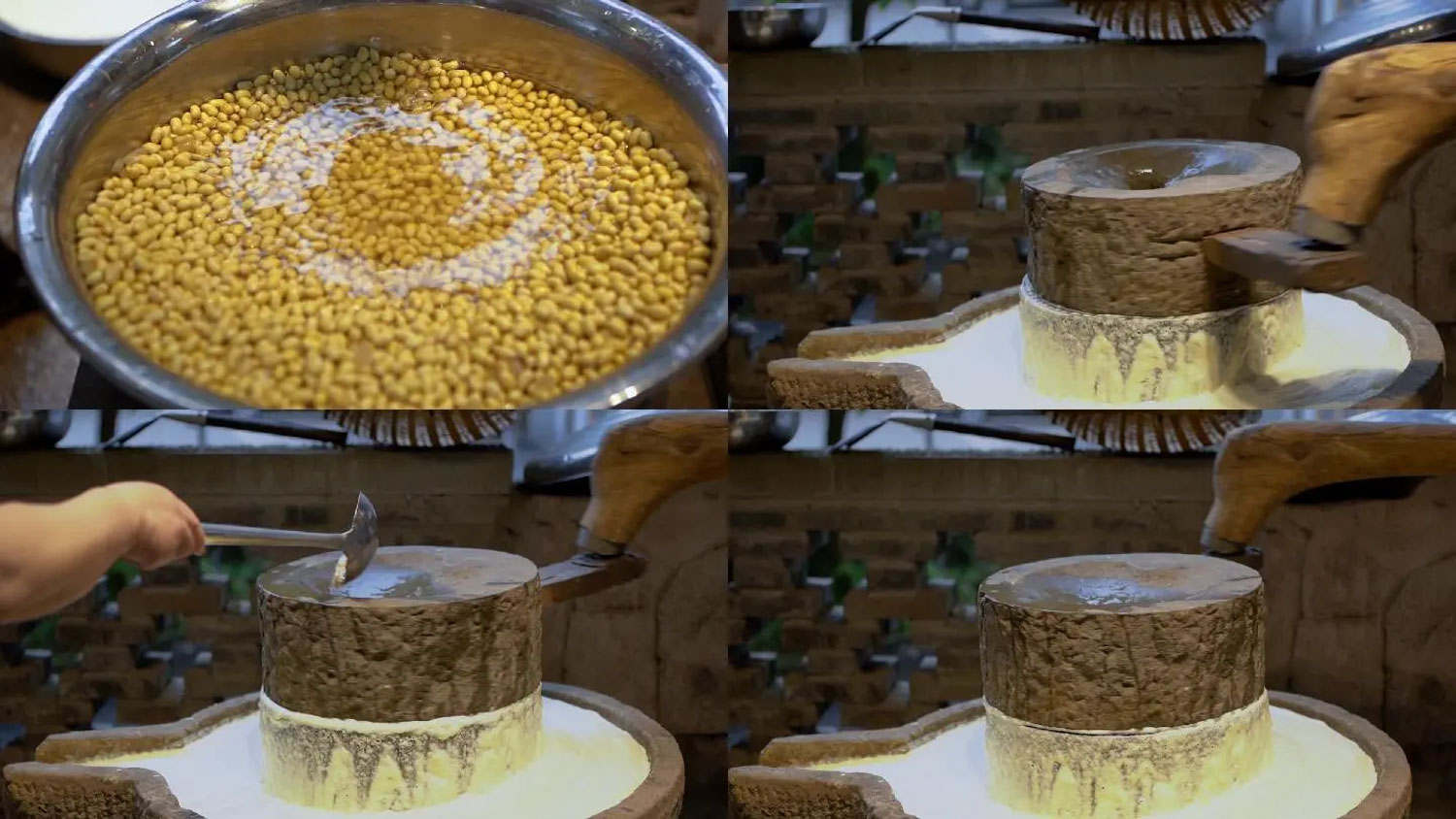

Soymilk Inline Refractometer // Why Has Tofu Lost Its Original Taste?

The reasons for the changes in the taste of modern tofu can be summarized into the following four aspects, combining the influence of changes in traditional craftsmanship and industrial production:

01/Changes in raw material quality

Raw material changes: traditional varieties vs. genetically modified varieties, fertilizers and pesticides affect traditional tofu. Local non-genetically modified soybeans (such as the “August Yellow” variety) are used, which have a long growth period and high protein content. In modern times, in pursuit of yield, high-yield improved varieties or genetically modified soybeans are generally used. These soybeans have high oil content but low protein content, which directly affects the accumulation of bean aroma substances. According to surveys, traditional soybeans currently account for less than 5% of the market.

02/Simplification of production process

Changes in process: High temperature of machine grinding destroys the flavor, steam cooking is different from firewood cooking, and the coagulants are different. Grinding method: Traditional stone mill low-speed grinding can retain the protein structure, while mechanical high-speed grinding produces high temperature to destroy aromatic substances. Boiling process: Slow cooking in a wood-fired iron pot can form a burnt aroma, while modern steam boiling temperature is insufficient and defoaming agents are used, resulting in a strong beany smell. Coagulant difference: Traditional brine/vinegar coagulation gives tofu a special flavor, and now chemical coagulants such as gluconolactone are mostly used.

03/Adjustment of production parameters

Adjust the ratio of beans and water: reduce costs and reduce the amount of beans used.

In order to extend the shelf life and improve the appearance, preservatives, whitening agents and other chemical substances are generally added. These ingredients will cover up the natural bean fragrance. Some merchants also use defoaming agents to speed up the production process.

Additives used: preservatives and whitening agents mask the aroma of soybeans.

The ratio of soybeans to water has changed from the traditional 1:8 to 1:12 or even higher, and the solid content of soybeans has decreased. Data shows that the amount of tofu produced per kilogram of soybeans in industrial production is more than 4 times that of traditional production, which directly dilutes the aroma of soybeans.

The concentration monitoring system plays an especially important role in soy milk production, which is mainly reflected in the following five aspects, combining automatic control and precise detection technology:

01/ Ensure the stability of product quality

Accurately control concentration: monitor the soluble content (such as protein and fat) in real time through the refraction principle, and control the concentration error within ±0.1%. For example, the yield of yuba production requires a concentration of 5.5% for optimal yield, and the system can automatically maintain this threshold. Process parameter optimization: dynamically adjust parameters such as cooking temperature and amount of coagulant added according to concentration data to ensure that the taste and nutrition of soy products meet the standards.

02/Improve production efficiency

Automatic adjustment: The system refreshes data every 5 seconds, and automatically triggers the valve to adjust the water intake when the concentration is abnormal, reducing manual intervention and downtime. Full process coverage: Dual measurement and control points are set at key nodes such as the raw pulp tank and bean/dregs mixing tank to achieve full-link monitoring from grinding to forming.

03/ Reduce production costs

Raw material savings: Avoid concentration fluctuations caused by traditional manual adjustments and reduce 10-15% soybean waste. Labor cost optimization: The soy milk concentration automation system can replace 80% of manual concentration detection positions.

04/ Strengthen food safety

Through real-time alarm functions (such as setting upper and lower limits of concentration), unqualified products can be intercepted in time to reduce the risk of excessive microorganisms caused by abnormal concentration. Compared with laboratory sampling, online monitoring can increase the speed of quality problem detection by 90%

Application suggestions: Enterprises need to calibrate inline refractometers regularly (recommended once a month) and set the flow rate appropriately (laminar flow is preferred) to improve monitoring accuracy. For factories above a certain scale, it is recommended to use an integrated system with a circulation pipeline to ensure detection stability.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *