- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2025-05-12

- Zhyq

- 107

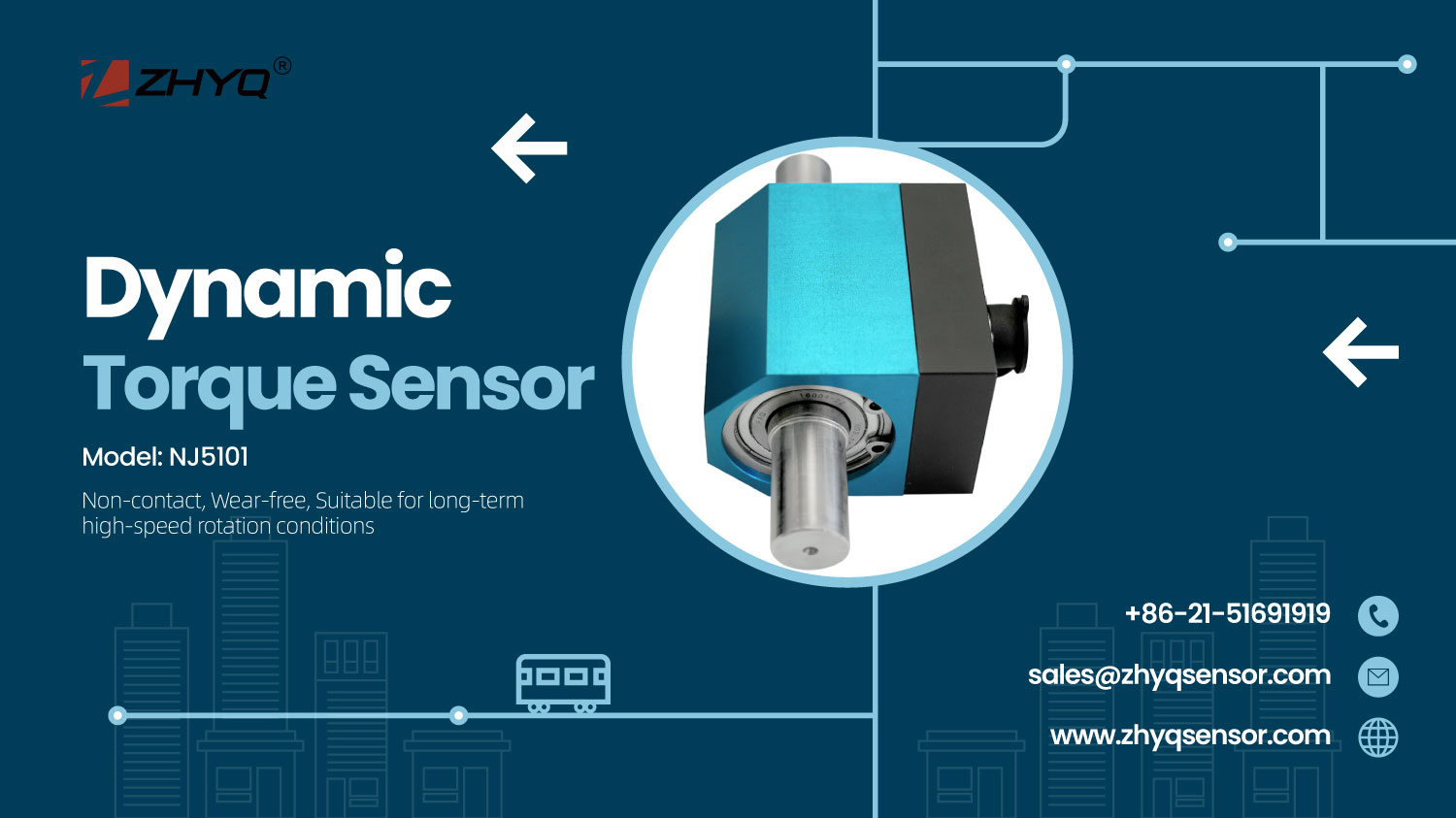

NJ5101 high-precision dynamic torque sensor makes all forces “visible and controllable”

NJ5101 high-precision torque sensor—industrial-grade product designed for harsh working conditions!

Core parameters: Range: 0.1~200N·m | Accuracy: ±0.1%FS | Speed range: 0~10000rpm | Protection: IP67

Technological breakthrough: built-in temperature compensation | anti-electromagnetic interference | wireless data transmission (optional)

Applicable scenarios: motor/engine testing | centrifuge | generator | reducer

[Industry pain points vs. NJ5101’s solution]

1. New energy vehicles: real-time monitoring of motor torque, dual guarantee of endurance and safety Pain points: Motor torque fluctuations lead to energy efficiency loss, and high risk of overload under extreme working conditions.

NJ5101’s solution: ✅ Dynamically monitor the output torque of the drive motor, optimize the response speed of the electronic control system, and improve the driving range; ✅ Real-time warning of overload threshold to avoid battery/motor damage and protect the safety of the high-voltage system.

2. Industrial robots: joint torque closed-loop control Pain point: Traditional encoders cannot directly sense load torque, and flexible grasping is prone to inaccuracy.

NJ5101 solution: ✅ Directly measure the torque of the robot arm joint to achieve “force-position” closed-loop control; ✅ Adapt to collaborative robots, 0.1% accuracy to facilitate precision assembly (such as 3C electronics, medical devices).

3. Smart Manufacturing: The “Golden Ruler” of Tightening Process Pain Point: Deviation of screw tightening torque causes product failure (such as loosening of automobile bolts).

4. Reducer: Accurate monitoring to reduce energy loss

✅ Real-time monitoring of torque data to verify whether the reduction ratio matches the design requirements ✅ Detect instantaneous torque peak, trigger shutdown protection or adjust motor output. Avoid damage to key equipment and reduce maintenance costs

NJ5101 solution: ✅ Integrated in the automated tightening gun, real-time feedback of torque data, and the yield rate increased to 99.99%; ✅ Data cloud storage, supporting process traceability.

[Why choose Shanghai ZHYQ’s NJ5101? ]

Excellent quality: industrial-grade material technology, stable output at -40℃~60℃;

Simple integration: elastic pin coupling or rigid coupling connection, 10-minute rapid deployment;

Worry-free service: 24-hour technical response | Free customized design

Leave Your Inquiry

Your email address will not be published. Required fields are marked *