- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2025-05-23

- Zhyq

- 99

Melt Pressure Transmitter Provides Key Data Support for the Injection Molding Process by Accurately Monitoring Changes in Melt Pressure.

1. Application scenarios and functions

Real-time pressure monitoring:

When the molten plastic is injected into the mold cavity, the melt pressure transmitter provides real-time feedback on the injection pressure (usually 80-120MPa) to ensure proper filling and avoid under-injection or overload. During the holding stage, the melt shrinkage is compensated by pressure closed-loop adjustment to reduce shrinkage marks and internal stress.

Process parameter optimization:

Combined with mold temperature and screw speed, the pressure parameters are dynamically adjusted to improve molding efficiency (such as shortening the molding cycle by 5%-10%).

Closed-loop control system integration:

Traditional injection molding machines rely on the oil pressure system to indirectly estimate the melt pressure, which has a large error. The melt pressure transmitter (such as the PT124 series) directly contacts the melt and outputs a 4-20mA or 0-10V signal to the PLC to achieve precise closed-loop control, and the yield rate is increased to 99.99%.

Special process adaptation:

Gas-assisted injection molding: During the gas injection stage, the melt pressure monitors the changes in the mold cavity pressure, optimizes the gas penetration path, and reduces the surface “fingerprint effect” and flow mark defects.

Production of thin-walled and precision parts:

High sensitivity (±0.05%FS/℃ temperature drift) ensures that tiny pressure fluctuations are captured to avoid warping caused by uneven filling.

2. Technical Principle and Design Features

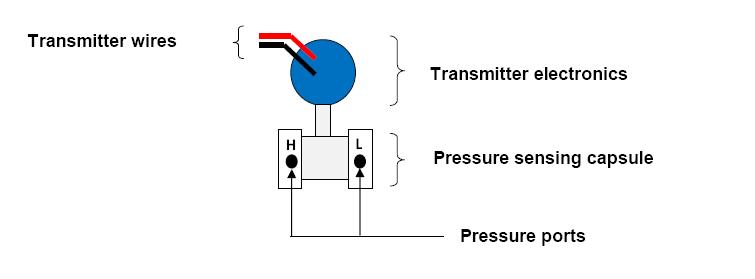

Working Principle :The transmitter has a built-in high-temperature resistant diaphragm (such as 316L stainless steel or PTFE coating), which converts the melt pressure into an electrical signal through the piezoresistive effect. The sensor core adopts a temperature compensation algorithm to eliminate the influence of thermal drift in an environment of -10℃~450℃ and ensure measurement accuracy (±0.5%FS).

Structural design: Diaphragm isolation: prevents melt solidification and blockage, suitable for high-viscosity materials (such as nylon, polyester). Modular packaging: IP65 protection level, dust and oil resistance, suitable for harsh working conditions of injection molding machines. Fast response: 5ms rise time, real-time feedback of pressure transients, avoiding process lags.

3. Core Advantages

ZHYQ was founded in 1999. Since its inception, it has been committed to the research and development, production and sales of melt pressure transmitters. Its melt pressure transmitter series has a high reputation in the domestic injection molding machine industry. Quality and performance are the foundation of an enterprise. Its PT124B series high-temperature melt pressure transmitter has the following characteristics

1. High precision and stability:

Long-term stability reaches 0.1%FS/year, resistant to 20Hz-1kHz mechanical vibration, and adapts to the high-frequency impact environment of injection molding machines. It has a wide pressure range (0-300MPa) and supports overload protection (safe overload 150%FS).

4.Summary:

PT124B series melt pressure transmitters have become the core components of the intelligent upgrade of injection molding machines through precise pressure monitoring and closed-loop control. The main advantages are:

1). Energy saving and cost control: By optimizing the injection pressure, the clamping force requirement is reduced, and the energy consumption of the equipment is reduced. Reduce material waste (such as gas-assisted molding can save 15%-30% of plastic).

2). Intelligent expansion: Support HART protocol and IoT integration to achieve remote monitoring and predictive maintenance, and extend mold life (such as reducing screw wear by 20%).

With the deep integration of industrial IoT and AI algorithms, their real-time data will drive the injection molding process towards adaptive optimization, and further achieve the goal of efficient and low-carbon intelligent manufacturing.

5. Selection and installation suggestions:

Range selection: Select the transmitter range according to the maximum injection pressure of the injection molding machine (usually 100-200MPa), leaving 20% redundancy.

Temperature adaptation: If the melt temperature exceeds 350℃, a metal alloy filling model (temperature resistant to 450℃) must be selected.

Installation configuration: The threaded interface is standardized (such as M14×1.5), directly embedded in the nozzle or barrel to avoid delays caused by the pressure pipe. The signal line needs to be shielded to prevent electromagnetic interference from affecting the output stability.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *