- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2025-06-03

- Zhyq

- 36

Coffee Drinks: The Secret Weapon Behind Standardized Drinks – Inline Process Refractometer

On supermarket shelves, a wide variety of coffee drinks are neatly displayed. Have you ever wondered how to achieve the exact taste of every bottle of the same drink from different batches and factories, whether it is a mellow Americano, a silky latte, a rich flat white, or a layered cappuccino? Behind this seemingly simple bottle of ready-to-drink coffee lies a complex and sophisticated industrial production process, and the core secret to ensure this “exactly the same” is an indispensable key sensor – an inline concentration meter.

From the precise roasting and grinding of selected coffee beans, to the efficient extraction and blending of coffee essence, to the subsequent homogenization and emulsification, high-temperature sterilization, aseptic filling, and rapid cooling, each link is closely linked and precisely controlled. However, the complexity of the process alone is not enough to achieve perfect standardization. Even the slightest concentration deviation in the formula – 1% more or 1% less coffee solids, a slight fluctuation in the sugar and milk fat ratio – is enough to cause obvious flavor differences in the mouth of consumers, causing the entire batch of products to deviate from the standard and damage the brand reputation.

Relying on manual quality control? Far from enough! Although human senses are sharp, they are easily fatigued, with subjective differences and large errors, and cannot meet the stringent requirements of high-speed, continuous, and large-scale production. At this time, the precise sensor system becomes the “super sense” on the production line. They are like tireless “precision sentinels” that monitor every key parameter of production in real time.

On a standard coffee production line, we can see weighing sensors ensuring the proportion of raw materials, flow meters controlling the flow rate of liquids, and thermometers ensuring accurate heat treatment. However, the little-known but crucial optical monitoring instrument plays the role of “guardian of flavor” – the online process refractometer (usually based on the principle of refraction, such as ZHYQ’s CZ-C inline process refractometer).

Inline process refractometer: the key tool to accurately lock the flavor code

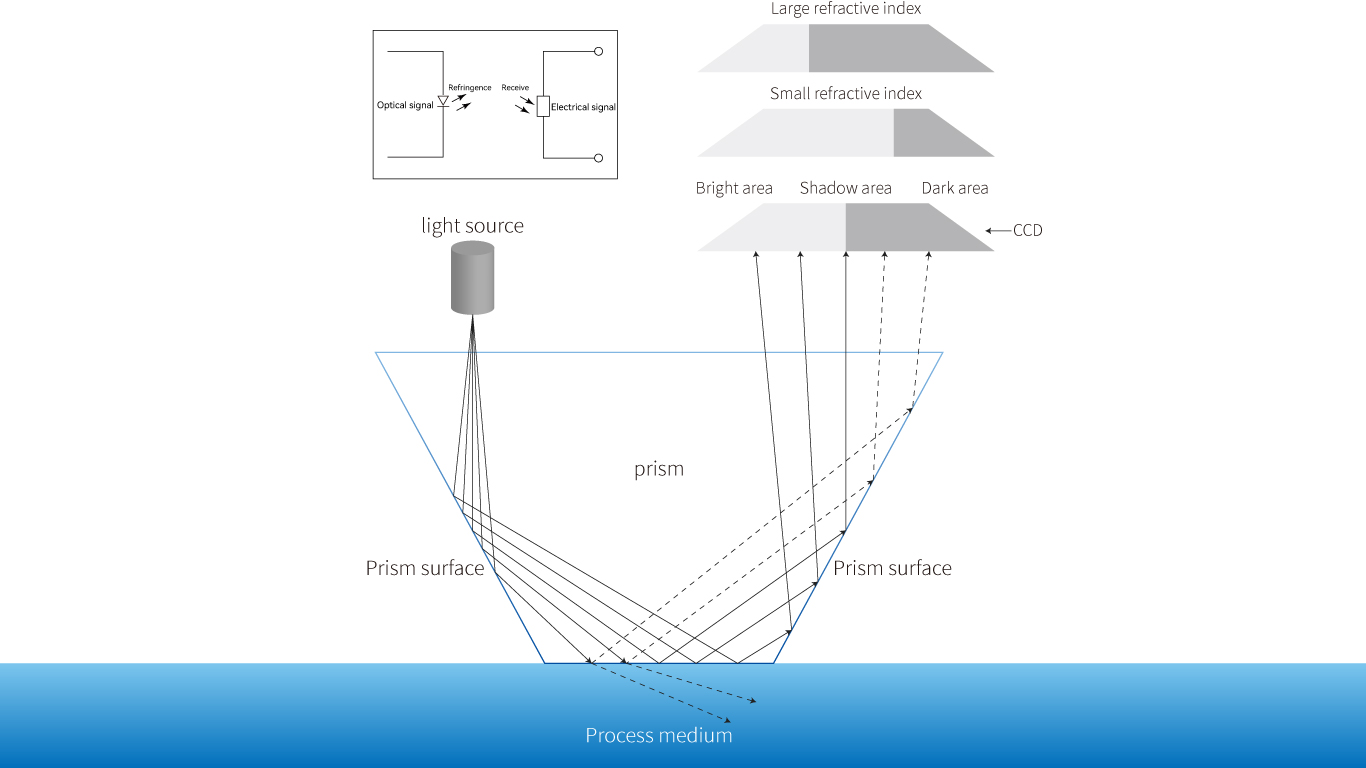

1. Principle: With a sturdy and durable sapphire prism as the core component, the inline process refractometer measures the physical property of the solution’s refractive index to accurately calculate the proportion of solutes (such as coffee soluble solids, sugar, milk solids, etc.) in the solution, that is, the core concentration value, in real time, continuously, and non-contact.

2. Core value: It is like a “golden ruler” and “flavor radar” on the production line, “scouting” the slightest changes in product concentration 24 hours a day, 7 days a week, to ensure that the key flavor indicators of every drop and every bottle of coffee drink are strictly locked within the preset gold standard.

Key application points of inline process refractometer in coffee production:

1. Extraction stage – the cornerstone of flavor: Real-time and accurate monitoring of the concentration of coffee concentrate ensures that the extraction intensity (such as soluble solids content) of each batch is highly consistent, locking the core flavor tone of coffee from the source, and eliminating the blandness of insufficient extraction or the bitterness of over-extraction.

2. Blending and dilution stage – precise execution of the formula: During the syrup addition, milk/non-dairy creamer mixing, or final product dilution stage, the inline process refractometer automatically and continuously monitors the concentration of the mixture. It is like an intelligent “conductor”, real-time linkage control system (such as regulating valve, metering pump), automatic and accurate addition of water or other ingredients, to ensure that key ratios such as sugar content and milk-coffee ratio are accurate.

3. After homogenization/before filling – the ultimate line of defense for finished products: Before the finished product enters the filling line, the inline process refractometer continuously monitors the final mixture in real time. Once the concentration is detected to deviate from the standard range, the system immediately links the automated sorting device to accurately divert and remove unqualified products, and never allow a bottle of product that does not meet the flavor standards to flow into the market.

4. Raw material acceptance and process control – full-process protection: It can also be applied to the concentration acceptance of key raw materials (such as syrups and milk-based materials), as well as the quality monitoring of intermediate process products (such as mixed liquids), to build a quality defense line for the entire chain.

Working together to create perfect flavor

In the huge coffee beverage production system, various sensors perform their duties and work together. The inline process refractometer, with its accurate, real-time, online control of the core attribute of the beverage – concentration, has become the core hub for flavor consistency throughout the entire chain “from extraction to filling”. The value it brings far exceeds the quality control itself:

1. Ultimate flavor stability: Ensure that every bottle of beverage perfectly reproduces the preset mellow, silky or rich taste, and delivers on the quality promise to consumers.

2. Significant cost reduction and efficiency improvement: Maximize raw material utilization, reduce waste caused by incorrect proportions; reduce manual sampling costs and downtime; optimize process parameters and improve overall production efficiency.

3. Build a solid quality defense line: Provide objective, reliable and real-time data guarantee for product quality and batch stability, and greatly reduce quality risks.

4. Core of digital upgrade: Concentration data is the core parameter for realizing digital and intelligent control of coffee production, providing a solid data foundation for process optimization, quality traceability and new product development.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *