- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2022-12-09

- Zhyq

- 135

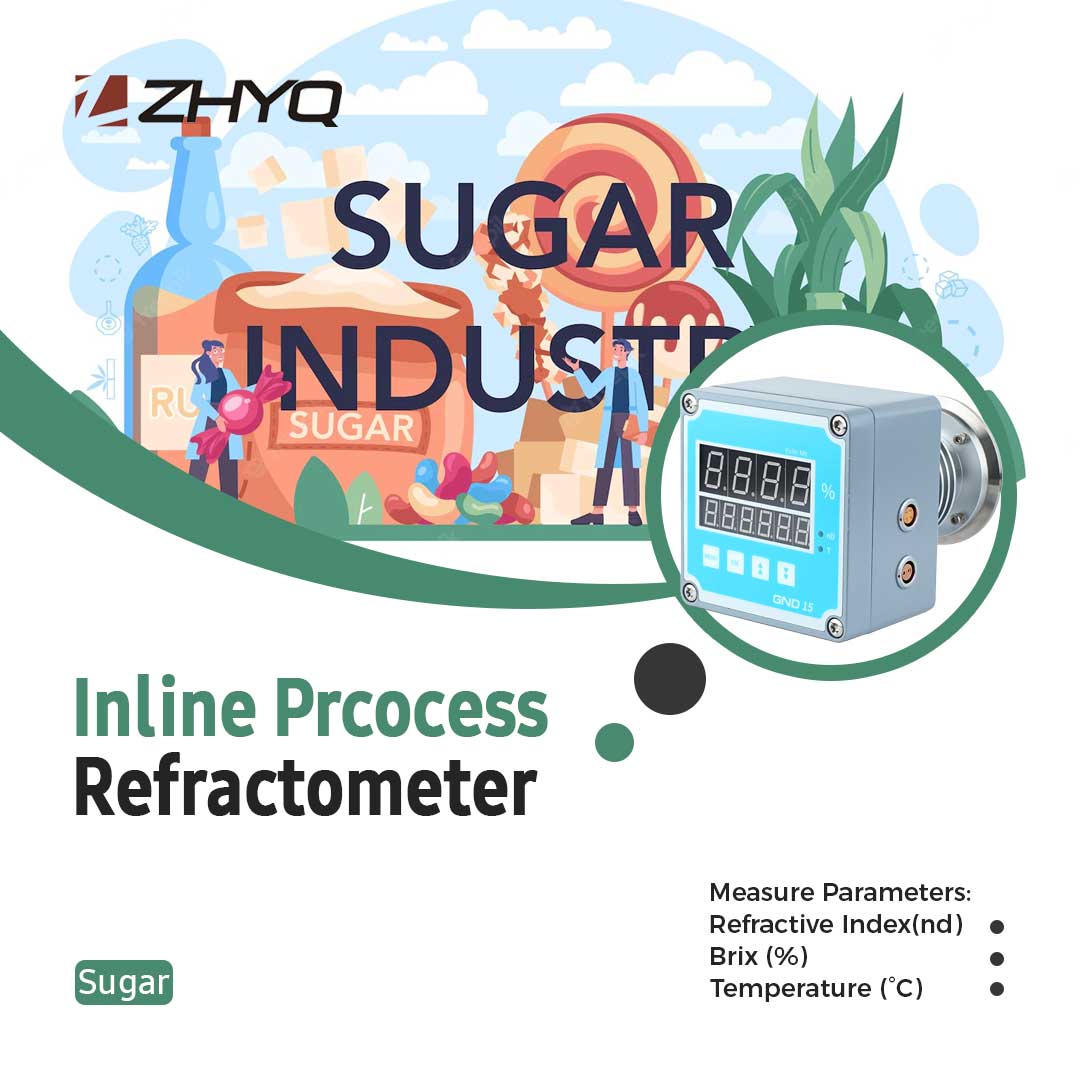

Application of CZ-B inline process refractometer in sugar processing

Edible sugar manufacturing is a delicate process that requires process control and instant, accurate Brix (massecuite solids content) measurement of raw and in-process liquids for best product quantity and quality, Only high-quality liquid and crystal sugars are acceptable. In crystal sugar manufacturing, the absolute goal is to produce the maximum amount of even quality crystals, avoiding fines and conglomerates.

As sugar refining is a highly energy-intensive process where raw juice is subjected to multiple processing steps to remove impurities, the right process control tools help to maximize yield and minimize the cost of production. Overall, the sugar industry is a large water consumer as each production step requires water. The water and energy consumption during manufacturing can be significantly reduced, contributing to mill’s or refinery’s sustainability, by using modern technology equipment, such as ZHYQ CZ-B Inline Process Refractometer.

Sugar crystallization is often the main production process, and mass-producing quality and constant sugar at a competitive price require robust measurement devices that are not affected by varying process conditions from the liquid phase to massecuite nor by increasing crystal content during a strike.

Supersaturation is the driving force of crystal growth, and the speed of crystallization depends on this multivariable function of several parameters. Supersaturation has an optimal range, where sugar crystals grow evenly and widely. Outside the range, the crystals will stop growing and might even melt or start to form new crystals spontaneously creating fines and conglomerates requiring reprocessing.

Accurate measurement of Brix and concentration

The role of CZ-B:

- Increased quality of liquid and crystal sugars

- Sugar products precisely according to recipe

- Assurance that liquid bulk sugar and molasses meet specifications

- Optimized extraction process by minimizing the usage of water which needs to be evaporated at a later stage

- Energy savings by adapting product flow to the capacity of the evaporators

- Control over feed juice to adjust the concentration with the capacity of the separation columns extending the intervals between recovering cycles and prolonging the lifetime of the columns

- Monitoring tool of supersaturation over the complete strike of crystallization

- Implementation of automatic and accurate seeding of the vacuum pan.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *