- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2024-06-13

- Zhyq

- 158

Online Viscometer Is Widely Used in the Juice and Dairy Industry

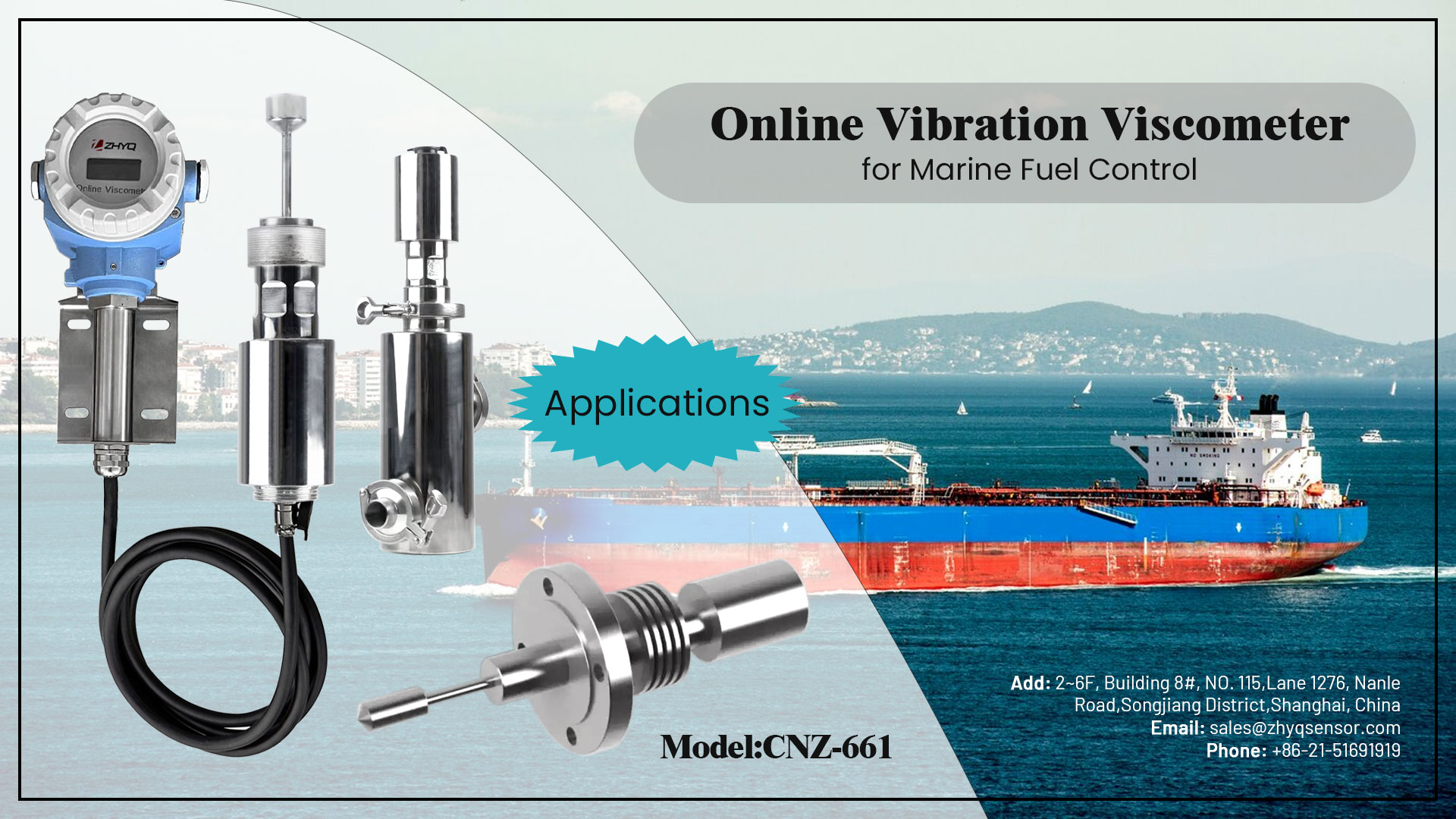

Working principle

The working principle of the online vibration viscometer is based on the principle of vibration. Its sensor probe moves with an amplitude of a certain frequency in the fluid. Due to the effect of fluid viscous damping, the amplitude of the probe will decay. In order to maintain the state of the probe amplitude before the action with the fluid, it is necessary to supplement the energy lost due to the viscous damping of the fluid. This part of the supplemented energy is related to the viscosity of the fluid, thereby realizing real-time online detection of the viscosity of the liquid.

Installation location

The online vibration viscometer is usually installed at key positions in the juice production line, such as the filtration link after juicing, the blending and homogenization link, or the pipeline before sterilization and cooling. These positions can ensure that the viscometer can accurately capture the viscosity changes of the juice at different processing stages, and provide timely and accurate data support for production control.

Function

1. Real-time monitoring: The online vibration viscometer can detect the viscosity of the juice in real time to ensure the stability of the juice during the production process. Through the viscosity data, production parameters such as juicing pressure and blending ratio can be adjusted in time to ensure the quality of the juice.

2. Quality control: Viscosity is one of the important indicators of juice quality. Through the detection of online viscometer, it can be ensured that the viscosity of the juice meets the product standards and improve the market competitiveness of the product.

3. Optimize production: Viscosity data can also be used to optimize the production process, such as adjusting the homogenization treatment time, optimizing the sterilization conditions, etc., to improve production efficiency and reduce production costs.

Advantages

1. Real-time: The online viscometer can detect the viscosity of the juice in real time and provide instant feedback for production control.

2. Accuracy: The vibration online viscometer has high measurement accuracy and can ensure the accuracy of the viscosity data.

3. Stability: Its structural integrated design has the advantages of stability and maintenance-free, and can operate stably for a long time under complex working conditions.

4. Flexibility: In the face of different production needs, sensor probes of different materials and rod lengths can be customized to adapt to different measurement environments.

Application Examples

Take a juice production line as an example. By installing an online vibration viscometer in the filtration link after juicing, the viscosity changes of the juice can be monitored in real time. When the viscosity data exceeds the preset range, the system will automatically alarm and adjust the squeezing pressure of the juicer or the pore size of the filter to ensure that the viscosity of the juice meets the product standards. At the same time, the viscosity data can also be linked with other control systems on the production line to achieve automated control of the production process.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *