- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2024-06-02

- Zhyq

- 164

Importance of Online Vibration Viscometer for Marine Fuel Control

Characteristics of ship fuel

1. High viscosity: Common ship fuels such as heavy oil have high viscosity at room temperature and are difficult to transport and burn directly, so viscosity control is required.

2. Complex composition: The quality and composition of ship fuel vary greatly, which has a significant impact on viscosity.

The role of online viscometer

1. Real-time monitoring: The online viscometer can monitor the viscosity changes of fuel in pipelines or tanks in real time to ensure that the fuel is within the optimal viscosity range.

2. Precise control: According to the reading of the viscometer, the control system can adjust the steam valve opening of the heater or the contactor of the electric heater to keep the fuel viscosity within the allowable range.

Specific control process

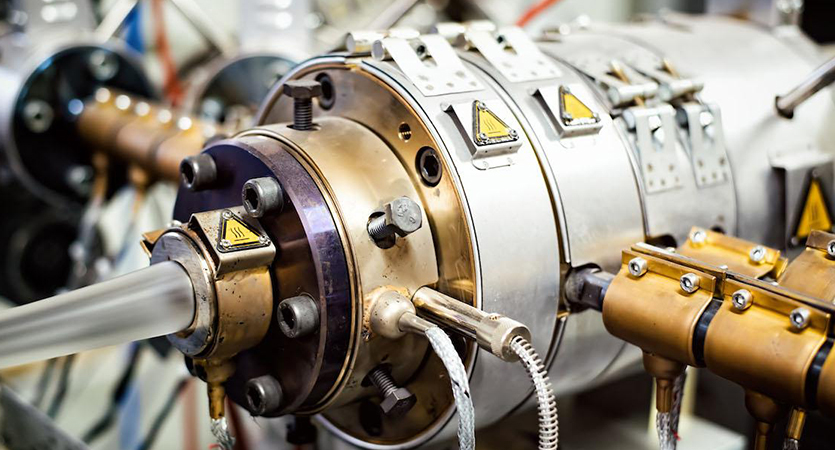

1. Install the viscometer:

Choose an online viscometer with high precision and strong anti-interference ability, such as a vibration viscometer.

Insert the viscometer directly into the ship’s tank or fuel pipeline to ensure that the installation is stable and does not affect the normal flow of fuel.

2. Set parameters:

Set the control parameters of the viscometer according to the type of fuel and the ship’s operating requirements, including viscosity range, alarm threshold, etc.

3. Real-time monitoring and feedback:

The viscometer monitors the fuel viscosity in real time and transmits the data to the control system.

The control system adjusts the working state of the heater according to the viscosity reading to keep the fuel viscosity within the set range.

4. Alarm and emergency treatment:

When the fuel viscosity exceeds the set range, the viscometer will send an alarm signal.

The control system takes corresponding emergency measures according to the alarm signal, such as increasing the heater power, adjusting the fuel flow, etc., to ensure that the fuel viscosity quickly returns to normal.

Advantages and effects

1. Improve combustion efficiency: By accurately controlling the fuel viscosity, ensure that the fuel is fully atomized in the cylinder and improve the combustion efficiency.

2. Reduce maintenance costs: Reduce equipment failures and downtime caused by excessively high or low fuel viscosity, and reduce maintenance costs.

3. Environmental protection and energy saving: Optimize the fuel combustion process, reduce exhaust emissions and energy consumption, and meet environmental protection requirements.

Summary

Online viscometers play a vital role in fuel control in the shipbuilding industry. By real-time monitoring and precise control of fuel viscosity, it can ensure that the fuel burns in the best condition, improve combustion efficiency, reduce maintenance costs and reduce environmental pollution. Therefore, it is necessary to widely use online viscometers for fuel control in the shipbuilding industry.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *