- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2022-12-02

- Zhyq

- 27

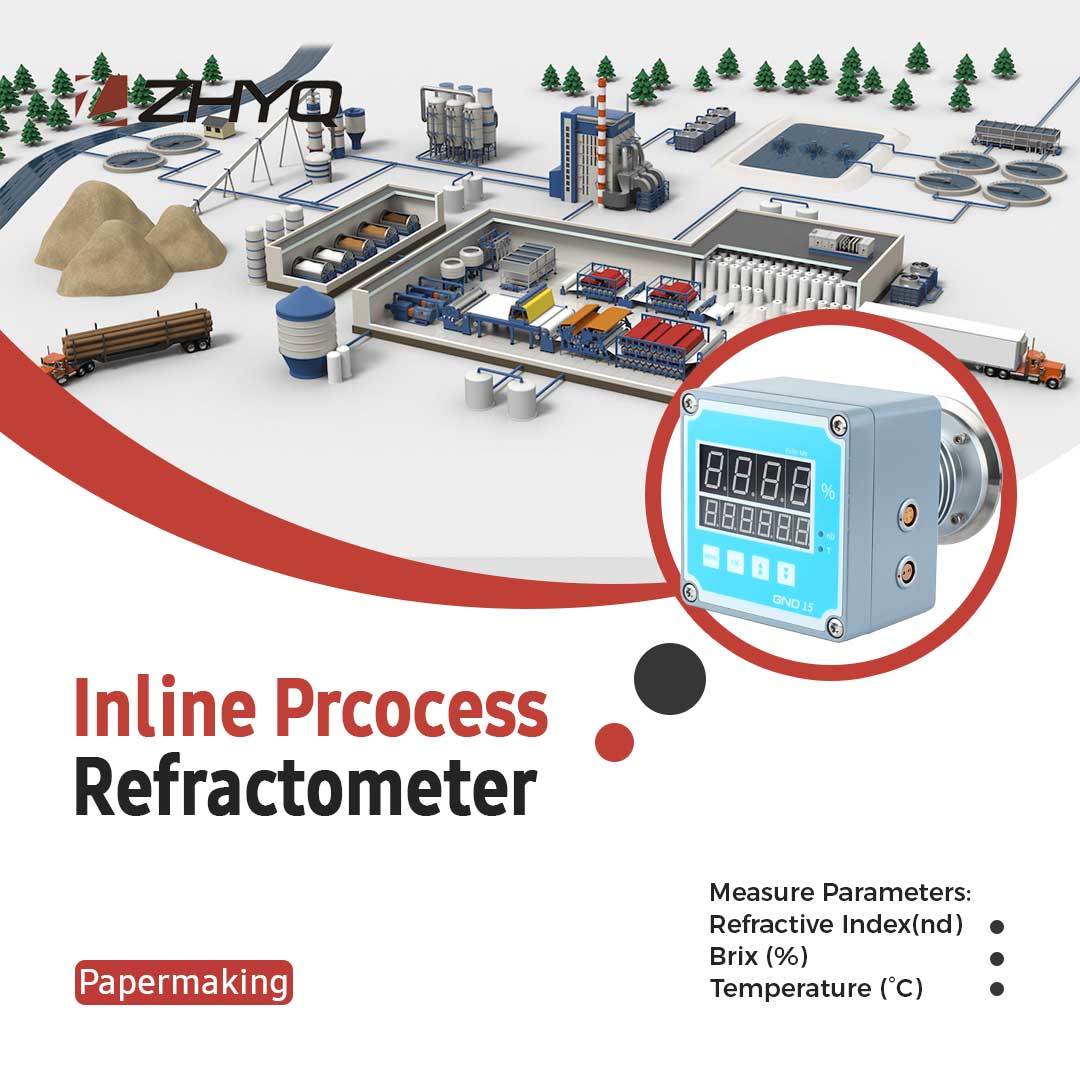

Application of Refractometer in Papermaking Industry

ZHYQ’s technologies help paper chemical companies, kraft chemical and semi-mechanical pulp mills, and paper and wood mills achieve high efficiency and essential properties in pulp, paper, paperboard, wood and timber products. main applications: 1.Pulp chemical recovery, 2.brown stock washing, 3.paper making and wood and timber processing.

1.In-line process control applications in the kraft chemical recovery:

Although the kraft recovery process is straightforward in principle, it is not easy to operate at high efficiency without proper process measurements. ZHYQ CZ-B Process refractometers for measuring black liquor and green liquor dry solids, liquid density, concentration and Total Titrable Alkali (TTA) in chemical recovery process to optimize energy intensive operations. As a result, the capacity of the evaporators can be increased, and the quality of white liquor can be improved by controlling continuously the TTA of the green liquor in the causticizing process. Furthermore, recovery boiler safety can be increased using a Digital divert control system in feeding black liquor solids to recovery boiler burners.

2.In-line process control applications in fiberline and brown stock washing:

Brown stock washing (BSW) can be considered the key operation influencing the economics of the pulping process, as well as the environmental load of the mill. The purpose of brown stock washing is to remove both organic and inorganic soluble compounds from the pulp suspension (brown stock), while using the lowest possible amount of wash liquor or water. Vaisala provides Process Refractometers for measuring and monitoring the Total Dissolved Solids (TDS) content in the pulp suspension.

Through optimization of the brown stock washing process and raising the black liquor solids content, mills gain immediate profits, cleaner and better quality pulp for bleaching, as well as optimized use of water, chemicals and energy.

3.In-line concentration measurement of sizing liquids and humidity measurement in paper mill:

In paper manufacturing it is important to control the paper sizing process as well as moisture content in the paper to an optimal level based on the end-use e.g. printing.

ZHYQ provides Process refractometers for the preparation and use of the size liquids, to ensure the right concentration of the cooked starch to storage, and to help stabilize sizing conditions and paper quality.

Typically, the paper mass is not measured directly, but paper mills use the hood air measurement to monitor and control the drying process indirectly, to avoid excess humidity in the hood. This measurement is especially demanding if there is a risk of condensation combined with elevated temperatures.

4.Wood and timber drying:

Wood drying is a complex process where measuring relative humidity plays an important role. Save energy and reduce costs by monitoring the humidity in your processes to avoid over-drying products and wasting energy. For accurate measurements, use the appropriate sensor, install the measurement device correctly, and calibrate the device regularly.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *