- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2024-07-27

- Zhyq

- 191

Sensor Core Introduction

ZHAO has 25 years of experience in R&D and production of core sensor technologies. It provides core components such as differential pressure cores, diffused silicon cores, and micro-fuse cores for sensors in China, the United States, the Middle East, Italy and other countries. It also shares experience data from industry applications with customers and is highly competitive in technology and price.

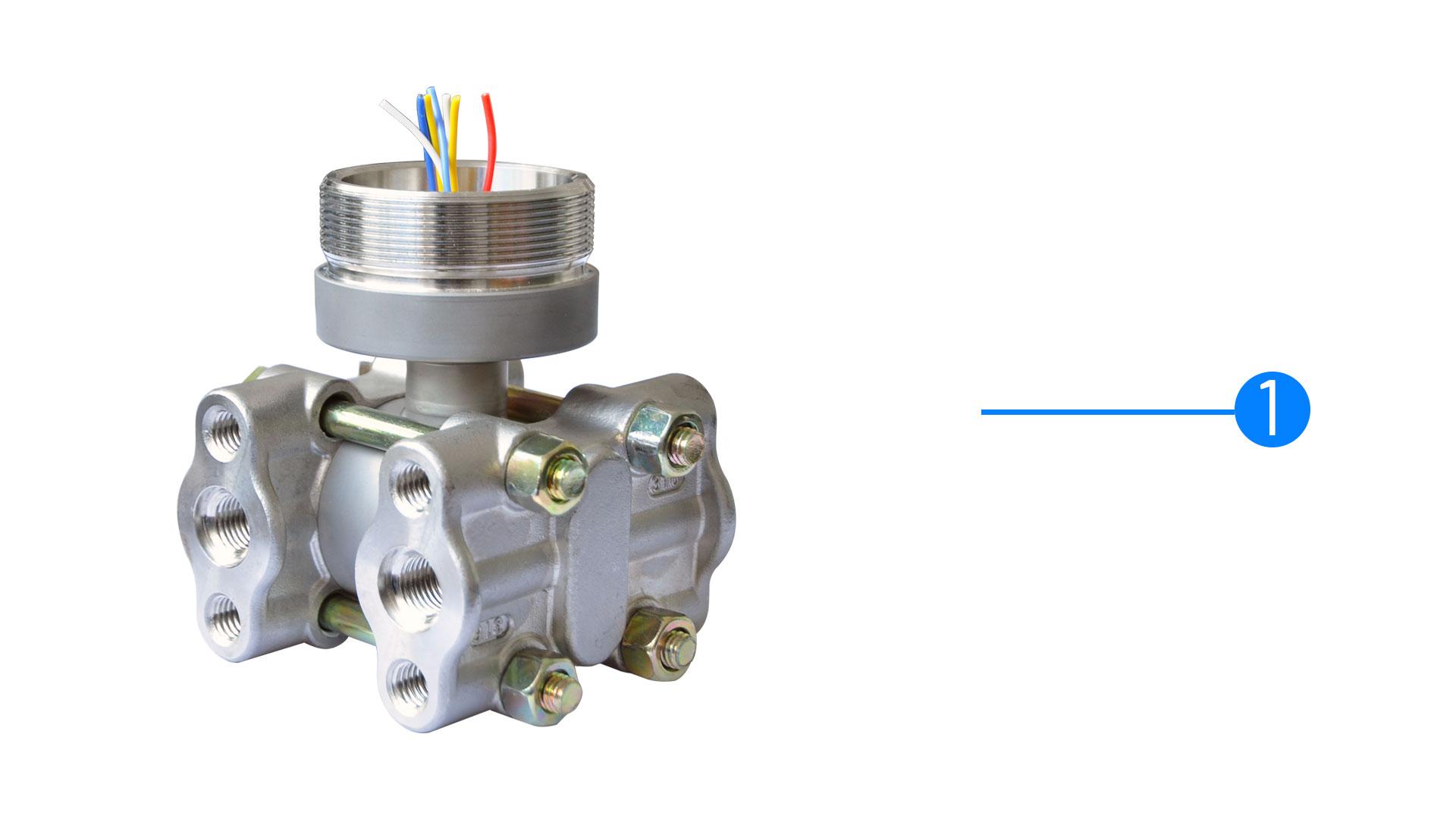

1. Monocrystalline silicon pressure core

When molten silicon solidifies, silicon atoms are arranged into many nuclei in a diamond lattice. If these nuclei grow into grains with the same crystal plane orientation, single crystal silicon is formed. Due to the uniformity of its internal structure, single crystal silicon has excellent mechanical, optical and thermal properties. zhyq Single crystal silicon pressure core has the characteristics of high precision and good stability

2. Diffused silicon pressure core

Traditional silicon semiconductor material is carved on polycrystalline silicon using micromachining technology. The technology is mature and the process is stable. It cannot be compared with single crystal silicon in terms of precision, but it has unique advantages in cost, versatility, and cost performance.

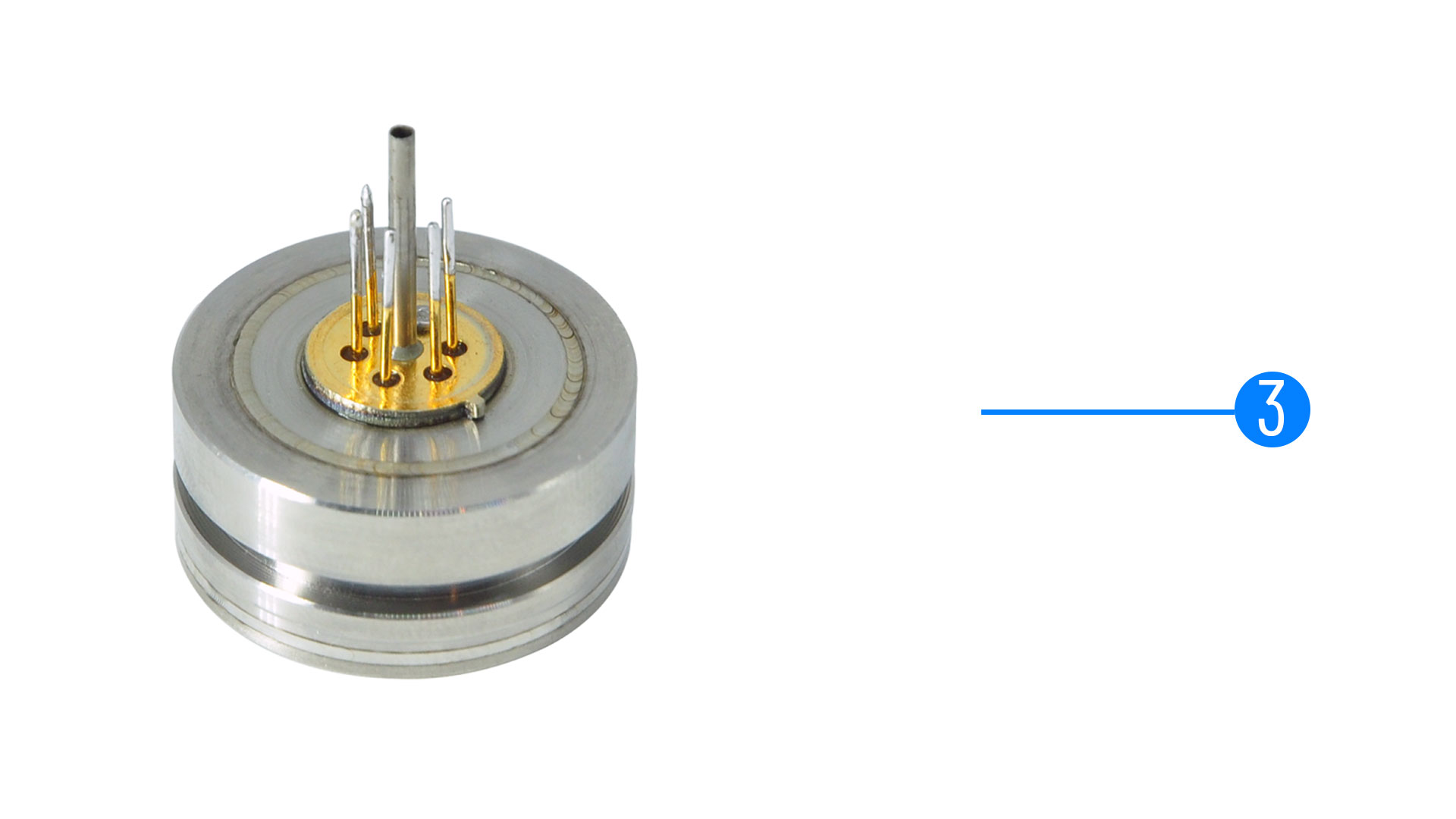

3. Glass micro-melting pressure core

A new technology developed by the California Institute of Technology in 1965. The back of the cavity is sintered with 17-4PH low-carbon steel by high-temperature glass powder, and the cavity is turned out of 17-4PH stainless steel. It is suitable for high-pressure overload and can effectively resist instantaneous pressure shock. Fluid media containing a small amount of impurities can be measured without oil filling and isolation diaphragm; stainless steel structure, no “O” type sealing ring, no temperature release risk. It can measure 600MPa (6000bar) under high pressure with a maximum accuracy of 0.075%.

However, it is difficult to measure a small range of glass micro-melting sensors, and the general measurement range is above 500kPa.

The pressure sensor based on MEMS (micro-electromechanical system) technology is a silicon strain gauge made of micro/Navistone bridge. It has the advantages of high output sensitivity, stable performance, reliable batch and good repeatability.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *