1. Application background

Wind power is an efficient, energy-saving and environmentally friendly way of producing electricity. The tower of a wind turbine is one of the important components of the wind turbine and has the dual functions of supporting the wind turbine and reducing the vibration of the unit. However, in actual operation, due to the complex forces and moments it is subjected to, the unit tower is prone to tilt and settlement under the combined unbalanced effects of various forces and moments, thus posing hidden dangers to the safe operation of the wind turbine. Once the wind turbine tower tilts and collapses, it will cause huge economic losses and even pose a threat to personal safety.

At present, during the operation of on-site wind turbines, manual inspection is mainly used to check and identify the degree of inclination or settlement of wind turbine towers. Although this inspection method is simple and easy to implement, it is labor-intensive and requires frequent inspections. Due to the carelessness and negligence of the staff, it is very likely that safety hazards will not be discovered in time, which will lead to major accidents. Based on this, the settlement sensor system is used to automate settlement monitoring, and through the processing of measured data, the settlement or tilt of the wind power tower can be effectively predicted.

2. Product Overview

The settlement sensor is an important bottom-level monitoring sensor in monitoring the settlement system of the project; the settlement sensor system is a precision instrument that measures the change of the liquid level settlement relative to the liquid level height between two or more points. Mainly used for monitoring vertical displacement and tilt of dams, nuclear power plants, wind power plants, high-rise buildings, mines, landslides, bridges, etc.

The settlement sensor system is generally installed on a measuring pier (pedestal) with the same height as the measured object or on the contour line of the wall of the measured object. It usually uses a modular automatic measurement unit to collect data and is connected to the computer through wired or wireless communication to achieve Automated observation.

3. Composition of monitoring system

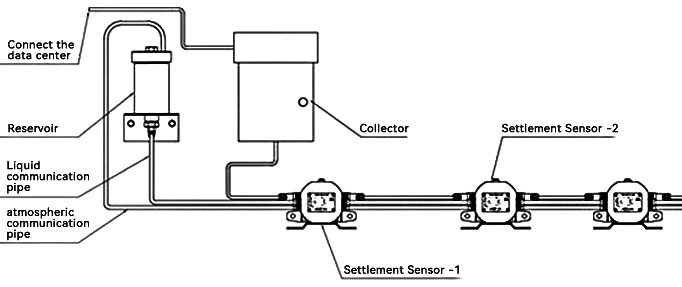

The settlement monitoring system consists of a collector, a reference point settlement monitoring sensor and several monitoring point settlement monitoring sensors. Through the sensor installation frame, data transmission cables, liquid connecting pipes and fixed accessories, atmospheric connecting pipes and fixed accessories, drying pipes, Liquid and other components. The installation methods are divided into two methods: flat-mounted installation on the measuring pier and side-mounted installation on the wall, which are selected according to the site conditions and design requirements.

4. System working principle

The settlement monitoring system consists of monitoring point sensors, reference point sensors, liquid storage tanks, collection systems, and data processing centers. The sensor monitoring system consists of at least three sensors, including one reference point and at least two monitoring points.

The acquisition system collects the data of monitoring points and the data of reference points in real time or according to set time and frequency and transmits it to the data processing center. The data processing center obtains the settlement data of the monitoring points through comprehensive analysis and comparison of the data collected in each time period. This is used to determine whether the monitored point is in a safe state.

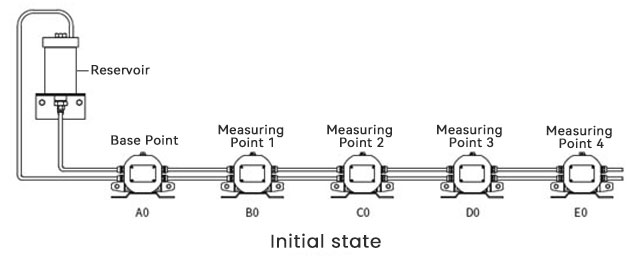

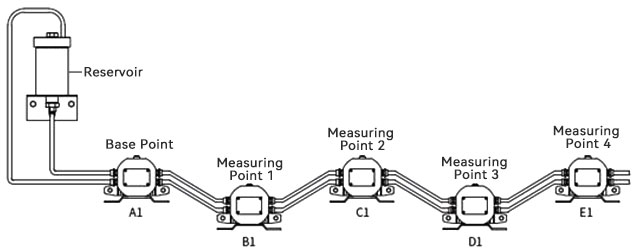

4. System working principle

The pressure of all settlement monitoring sensors is connected to the interface of the liquid storage container in series or parallel through the connecting pipe. After the liquid is injected into the liquid storage container, the liquid is transmitted to the pressure chamber of each settlement monitoring sensor through the connecting pipe, and the cavity is eliminated at the same time. The air in the body and pipes is used to reduce the impact of air on the accuracy of the sensor in hot and cold conditions; when the liquid level is completely stationary, the liquid levels in all connected containers in the system should be on the same geoid. At this time, each container The differential settlement of the liquid level is measured by the sensor.

In order to ensure the accuracy of measurement and application effectiveness, the distance between multiple monitoring points and adjacent monitoring points should be controlled within 30 meters. The specific spacing layout is determined by the design unit based on on-site working conditions.

5. Wind power tower project installation

When installing the monitoring system for the first time, it is necessary to follow the order of priority based on the on-site construction conditions. Reasonable planning of the installation sequence can effectively avoid rework caused by errors in the installation process.

The normal order is:

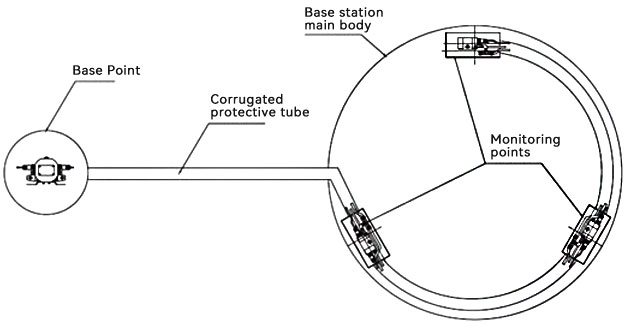

① Measure the horizontal height between the reference point and the monitoring point. The horizontal height of the reference point and the monitoring point should be consistent. The liquid storage tank should be higher than all measuring points.

② Determine the position of the monitoring point, and fix the external reference point to the installation plate of the reference point protection device; install the monitoring points 2, 3, and 4 in the air duct in an equilateral triangle position, and keep the distance as consistent as possible.

③ Install the settlement monitoring sensor and connect the liquid pipe, air pipe and communication cable.

④ Carry out communication test, connect the communication line to the collector, read the data and observe whether each settlement monitoring sensor is working normally.

⑤ Fill the system with liquid. The liquid filling direction is from the outside to points 2, 3, and 4 inside the air duct. After the liquid filling is completed, exhaust processing is required. Then open the liquid storage tank and fill it with silicone oil, and finally check each joint for bubbles and leakage.

⑥ Install insulation pipes between pipelines, wrap all corrugated pipes exposed on the ground with open insulation pipes, and then wrap and seal them with warning tape. Then connect the bellows joint to the protective cover and cover it with the protective cover.

⑦ Fix each monitoring point, connect the communication terminal of point 4 to the acquisition instrument, and read the data based on the data after 2 hours of rest after installation.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *