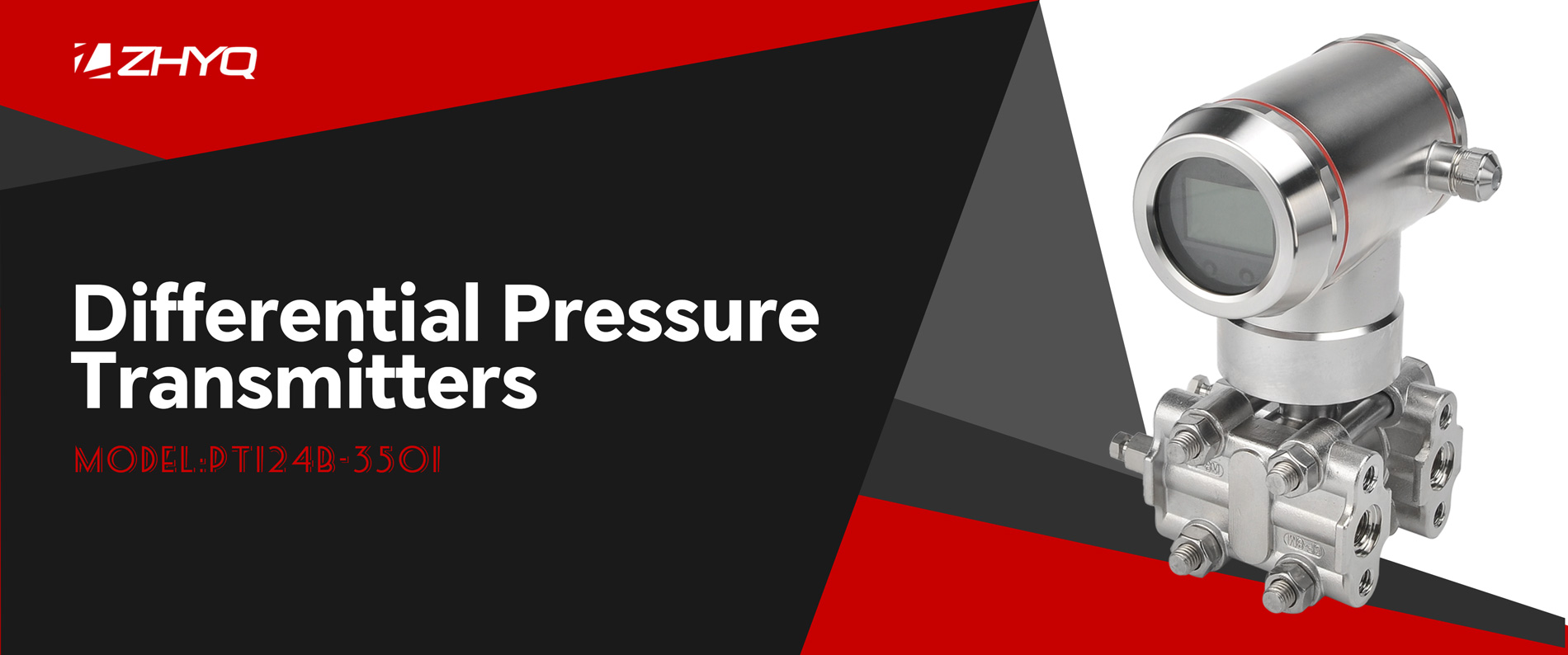

- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2024-05-30

- Zhyq

- 150

The Application of Online Vibration Viscometer in Jam Production, How Does It Affect the Production Process and Quality of Jam?

The application of online vibration viscometer in jam production is mainly reflected in the following aspects. These applications have a significant impact on the production process and quality of jam:

1. Real-time monitoring and control:

The online vibration viscometer can monitor the viscosity changes in the jam production process in real time. Since the viscosity of jam is directly related to its taste, texture and appearance, real-time monitoring and control of viscosity is crucial to ensure jam quality.

Through real-time measurement and control, production personnel can promptly discover and solve problems that arise during the production process, such as improper proportions of raw materials, too long heating times, etc., thereby avoiding product quality degradation or production failures.

2. Optimize the production process:

Based on the data provided by the online vibration viscometer, production personnel can adjust production parameters, such as heating temperature, stirring speed, etc., to optimize the production process. This helps ensure that the jam maintains a consistent viscosity and texture during production, improving the overall quality of the product.

3. Ensure product quality:

The application of online vibration viscometer can ensure that the jam maintains a stable viscosity during the production process. Through real-time measurement and control, each batch of jam can be ensured to have the same taste and texture, thereby improving product consistency and stability.

At the same time, real-time viscosity monitoring can also help reduce the production of substandard products and reduce production costs.

4. Improve production efficiency:

Since the online vibration viscometer has real-time monitoring and control functions, it can greatly shorten the production cycle and improve production efficiency. Production personnel can quickly adjust production parameters based on real-time data to ensure the smooth progress of the production process.

5. Data recording and analysis:

The online vibration viscometer can record viscosity data during the jam production process and provide production personnel with rich data analysis information. Through the analysis of these data, production personnel can understand the viscosity changes during the jam production process, providing scientific basis for the optimization of the production process.

6. Automated production:

The application of online vibration viscometer can promote the automation level of jam production. Through integration and cooperation with other production equipment, automatic control and management of the production process can be realized, labor costs can be reduced and production efficiency can be improved.

The application of online vibration viscometer in jam production has a positive impact on the production process and quality. Through real-time monitoring and control, optimizing production processes, ensuring product quality, improving production efficiency, data recording and analysis, and automated production, the efficient, stable and high-quality production of jam can be ensured.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *