- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2022-11-17

- Zhyq

- 171

Application of CZ-B inline process refractometer in beer production

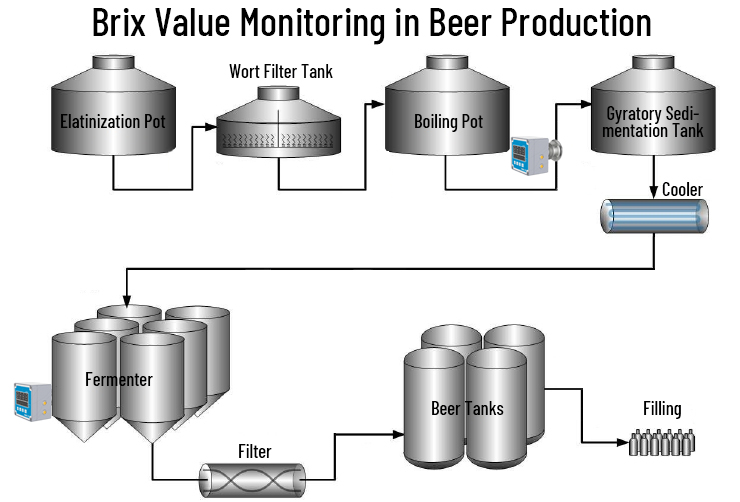

The beer production process can be divided into four processes: malting, saccharification, fermentation and packaging. Modern breweries generally no longer have malting plants, so the malting part will also be gradually stripped from the beer production process.

Installation of CZ-B inline process refractometer

CZ-B inline refractometer is suitable for installation in different processes of beer production process, and detects the content of soluble solids through the principle of detecting the refractive index of the solution. According to the different measurement requirements of each process, CZ-B can measure concentration (%), temperature (T), refractive index (nD)

1. Gelatinization pot In the gelatinization pot, malt and water are heated and boiled. At this time, natural acid converts insoluble starch and protein into soluble malt extract, which is called “wort“. The CZ-B inline process refractometer, usually installed on the outlet pipe of the gelatinizer, monitors the wort concentration online to maintain a stable and consistent concentration.

2. Wort filter tank Before the wort is pumped into the boiling pot, the wort husk is removed in the filter tank and hops and sugar are added.

In this process, it is necessary to rinse with water, so the concentration of wort will gradually decrease. CZ-B inline process refractometer, usually installed on the outlet pipe of the filter tank, monitors the wort concentration online, and can give a signal to stop the flushing in time to prevent excessive water use.

3. Boiling pot In the boiling pot, the wort is added with hops and boiled. The wort absorbs the taste of the hops and emits the unique aroma and bitterness of the beer, and reaches a certain wort concentration. This process is critical to the quality of beer. Without the need for a bypass system, the CZ-B inline process refractometer is usually installed directly on the boiler to monitor the wort concentration online, and can feed back the concentration signal to PLC or DCS for control. CZ-B inline process refractometer to help optimize boiling time, improve and stabilize beer quality.

4. After the gyratory settling tank is boiled, the wort added with hops is pumped into the gyratory settling tank to remove unwanted hop residues and insoluble proteins. The CZ-B inline process refractometer, usually installed on the outlet pipe of the boiler, monitors the hot wort quality online.

5. After the cooler wort is cooled, yeast will be added and pumped into the fermenter. CZ-B inline process refractometer, usually installed on the outlet pipe of the cooler, monitors the quality of the wort after cooling online.

6. Fermentation tank In the fermentation tank, the yeast decomposes the sugar in the wort into alcohol and carbon dioxide. After about a week, a “tender beer” can be produced, and then it matures after dozens of days. The CZ-B inline process refractometer, usually installed directly on the fermenter, instantly monitors changes in total concentration to monitor conversion, degree of fermentation and alcohol content.

7. After the fermentation by the filter, most of the yeast is deposited at the bottom of the tank, and this part of the yeast needs to be recycled and reused. The resultant “draught beer” is pumped into maturation tanks. Here, the remaining yeast and insoluble proteins are further precipitated to mature the style of the beer. The aged and matured beer is filtered out of all remaining yeast and insoluble proteins in the filter, and it becomes the sake to be packaged. CZ-B inline process refractometer, usually installed on the outlet pipe of the filter, monitors beer quality online.

8. The online refractometer for filling and demarcation can also be installed at the outlet of the sake tank, which is used for online demarcation of different varieties of beer, or beer and CIP cleaning liquid, and has an output signal to DCS, which is convenient for filling switching between different varieties of beer , and can reduce the beer loss caused by CIP cleaning.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *