- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2024-10-17

- Zhyq

- 30

How to choose an inline process concentration meter for starch sugar production?

Selecting an online process concentration meter suitable for the starch sugar production process requires comprehensive consideration of many factors. The following are some specific selection points:

1. Adaptability of measurement principle:

1.1 Refractometer: If the composition of the solution in the production process is relatively simple and stable, and the concentration change is mainly reflected based on the effect of the solute on the refraction of light, then the refractometer is a good choice. It has a good measurement effect on most starch sugar solutions and can respond quickly to concentration changes. However, it should be noted that this type is greatly affected by factors such as temperature and pressure. When the temperature and pressure of the production environment fluctuate greatly, it is necessary to equip temperature compensation and other devices to ensure the measurement accuracy.

1.2 Conductivity online concentration meter: For solutions involving more electrolyte components in starch sugar production, or links where ion concentration changes need to be monitored, conductivity concentration meters are more suitable. For example, in the ion exchange purification process of starch sugar, the removal of ions in the solution can be monitored by a conductivity concentration meter to judge the working effect of the ion exchange resin. However, if there are a large number of non-electrolyte impurities in the solution, it may interfere with the measurement results.

1.3 Sound velocity online concentration meter: If there is a requirement for non-contact measurement in the production process, or the solution has a high viscosity and a complex composition, the sound velocity concentration meter can be considered. It is not affected by factors such as color and turbidity in the solution, and can accurately measure the propagation speed of ultrasound in the solution, and then deduce the concentration. However, its measurement results are also easily affected by environmental factors such as temperature and pressure.

1.4 Density-type online concentration meter: If high-precision concentration measurement is required, and there is a clear correspondence between the density and concentration of the solution, then the density-type concentration meter is a better choice. It can directly measure the density of the solution without being disturbed by changes in other physical properties of the solution, but the equipment is relatively large and requires a certain amount of space for installation and use.

2. Measurement accuracy and stability:

2.1. Accuracy requirements: Select a concentration meter based on the accuracy requirements for concentration control in the starch sugar production process. For example, when producing products such as high-purity crystalline glucose, the concentration measurement accuracy is required to be high, and a high-precision concentration meter needs to be selected; while for some production links that do not require particularly strict concentration accuracy, such as the initial preparation stage of starch milk, a concentration meter with slightly lower accuracy can be selected to reduce costs.

2.2 Stability: It is very important whether the concentration meter can maintain stable measurement performance during long-term operation. It is necessary to select a concentration meter with good stability, which can work continuously in a complex production environment to avoid loss of control of the production process due to instrument failure or measurement deviation. You can check the product manual, user reviews, and manufacturer’s technical support of the concentration meter to understand its stability.

3. Corrosion resistance and cleanliness:

3.1 Corrosion resistance: Starch sugar production may come into contact with some corrosive substances, such as acid and alkali. Therefore, the material of the concentration meter needs to have good corrosion resistance and be able to be used for a long time in harsh chemical environments. For example, the use of stainless steel or special anti-corrosion coatings can effectively improve the corrosion resistance of the concentration meter.

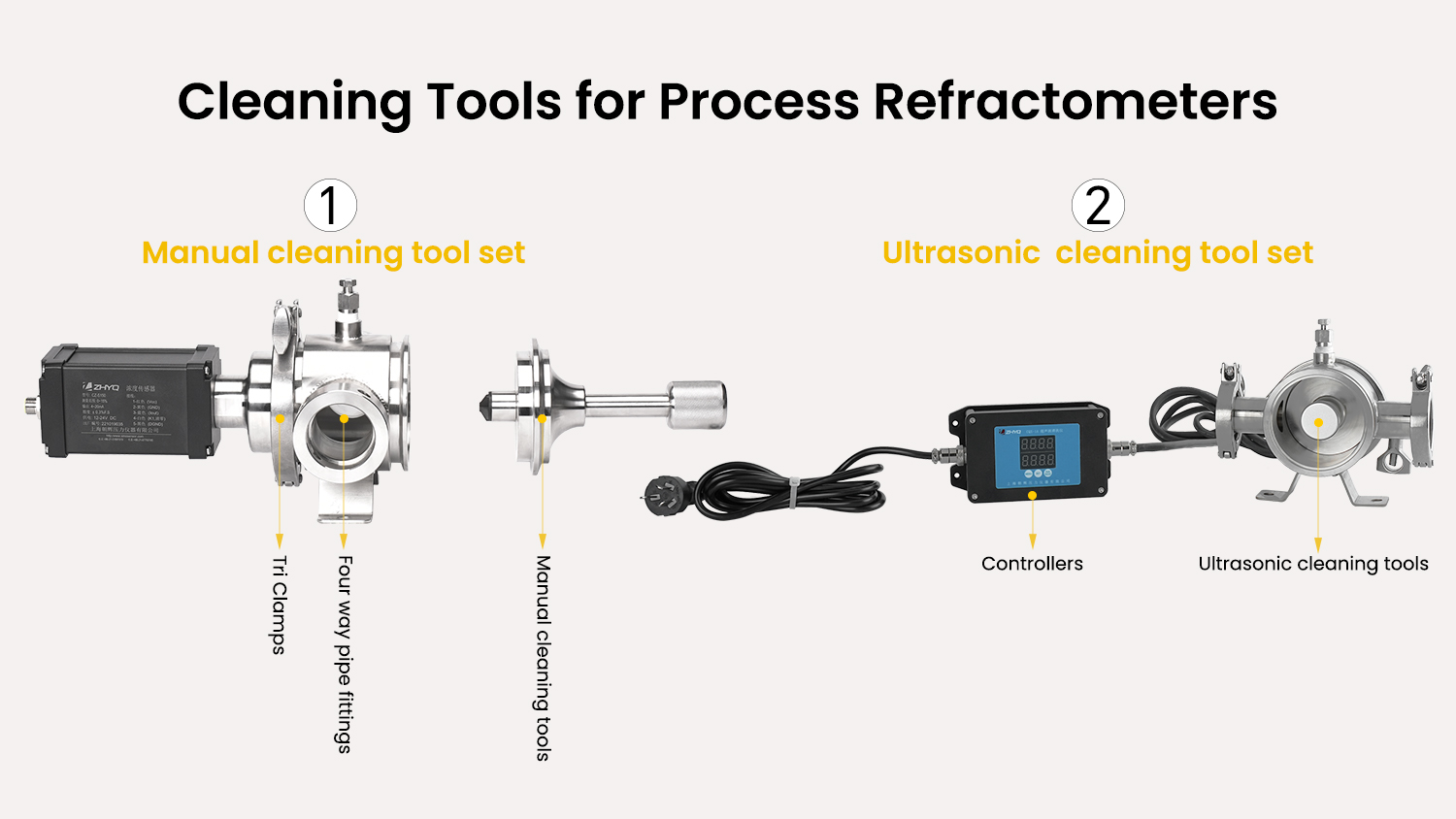

3.2 Cleanliness: The concentration meter needs to be cleaned and maintained regularly during the production process to ensure the accuracy of the measurement. Choosing a concentration meter with a simple structure and easy cleaning can reduce the difficulty and time of cleaning and improve production efficiency. At the same time, pay attention to whether the sensor part of the concentration meter is easily blocked by impurities in the solution to avoid affecting the measurement results.

4. Response speed and real-time performance:

4.1 Response speed: During the starch sugar production process, the concentration may change rapidly, especially in some production links with faster reaction speeds, such as the hydrolysis reaction of starch. Therefore, it is necessary to select a concentration meter with a fast response speed, which can track the concentration changes in time so that the operator can adjust the production process parameters in time.

4.2 Real-time performance: One of the main advantages of online process concentration meters is the ability to monitor concentration changes in real time. It is necessary to select a concentration meter with good data transmission and processing capabilities, which can transmit the measurement results to the production control system in time, and realize real-time monitoring and automatic control of the production process.

5. Compatibility and scalability of equipment:

5.1 Compatibility: The concentration meter needs to connect and communicate with other equipment and control systems at the production site, so it is necessary to choose a concentration meter with good compatibility. For example, it can support common communication protocols (such as RS485, Modbus, etc.) to facilitate integration with PLC, DCS and other systems on the production line.

5.2 Scalability: With the expansion of production scale or improvement of production process, it may be necessary to expand or upgrade the functions of the concentration meter. Therefore, it is necessary to choose a concentration meter with certain scalability, such as increasing the number of sensors, expanding the measurement range, etc., to meet future production needs.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *