- Pressure Sensor, Pressure Transducer, Pressure Transmitter

- 2023-08-18

- Zhyq

- 150

Application of Viscometer in batter preparation and coating process control

Batters mixes are widely used as a coating for deep-fried foods and in many other products including cakes, waffles, doughnuts, biscuits, meat, breads, pancakes, etc. When used as coating, the batter is typically applied by dipping, or spraying onto continuous baking drums and oven bands. Depending on the type of food product, the processing objectives and challenges may be different but one thing is fairly certain – the food companies strive to meet their requirements of consistency, quality and freshness, helping them develop innovative products, while lowering production costs and easing maintenance.

Application

Viscosity is crucial to production of batter mixes. Such systems typically consist of a number of dispersed phases such as flour, fat, water and air. Sufficient viscosity is required to stop phase separation during mixing, floor time and baking in the oven. For highly viscous batter systems, there is usually sufficient viscosity to stop phase separation and to trap and retain air (during bread production). However, for less viscous batter systems – wafers and puddings, can result in loss of air beaten into the batter during mixing and separation of solids which can be detrimental to the end product quality.

Cake batters need to be sufficiently viscous to prevent loss of gas bubbles during mixing, since these bubbles are recipients of the gas produced by raising agents and steam, which cause expansion and reduce batter density. Batter becomes thinner when heated up in the oven, thus increasing the likelihood of phase separation of the denser components, such as starch granules, which may sink to the bottom of the baking tin. The separation of recipe components therefore needs to be prevented by maintaining the right viscosity up to the point where the structuring is set.

The quality of foods such as soups, sauces, gravies, custards, flans, desserts, and baked products, to name a few, depend heavily on structure forming properties of materials such as starch which in turn can be controlled by monitoring its viscosity. Due to incorrect viscosity of the prepared mixture, after starch material is cooked, the granules swell and become fragile and can break down under shear. It can badly affect the characteristic eating quality of the food.

Viscosity is the key to achieve target properties in each of the following steps in the food industries involving batter production:

- Batter Preparation Unit (Mixer): This step is the preparation of batter mixes involving dosing correct amount of powder into the mixing system, where it will meet correct water supply. Generally, batter mixes are prepared on a batch basis and discharged to a holding tank prior to use. The prepared mix must be consistent and must have the correct viscosity characteristics for further processing steps as well as the end product quality.

- Applicator Unit (Coating): The prepared batter system in the batter mixer is passed through heat exchangers to get the optimal temperature which may be then applied/sprayed onto the food to be coated with the batter mix before further processing. Correct viscosity during the coating process is the key to the process efficiency and the end product quality.

Leave Your Inquiry

Your email address will not be published. Required fields are marked *

Related news

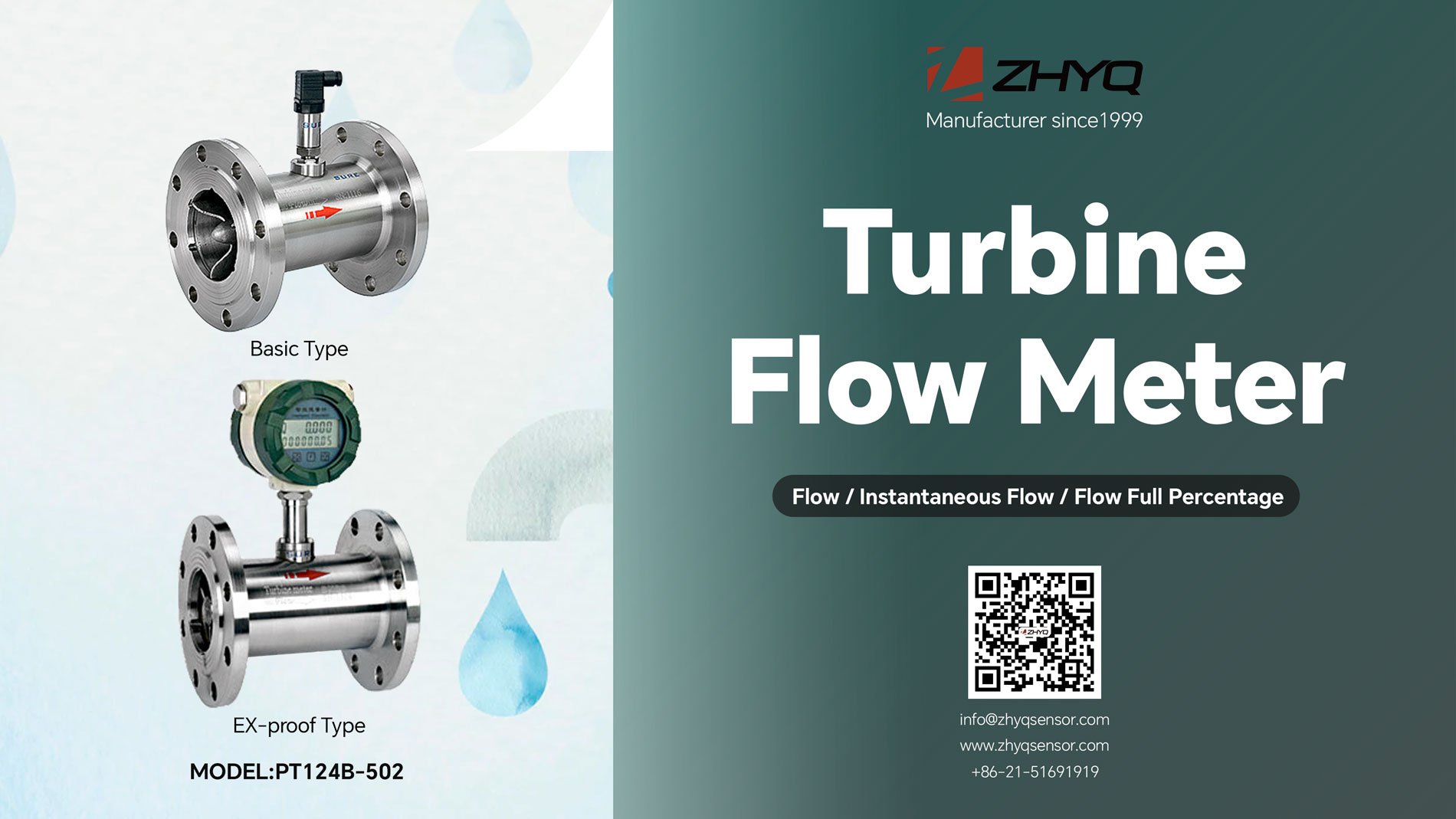

PT124B-502 high precision stainless steel explosion-proof flange liquid oil diesel fuel turbine flow meter

2023-04-28