In flammable and explosive industrial environments such as petrochemical plants, coal mines, and power station boilers, the safety and accuracy of pressure measurement are directly linked to production safety and operational efficiency. The PT124B-280 series explosion-proof pressure transmitters, featuring flameproof and explosion-proof construction, corrosion resistance, and stable measurement performance, have become an ideal choice for such demanding conditions. This article provides a comprehensive overview of this industrial “safety guardian” for pressure measurement, covering its core advantages, application scenarios, technical features, and installation and operation guidelines.

1. Core Advantages: Designed for Harsh Environments

Flameproof and explosion-proof design for all-round safety:

Specifically suitable for explosive gas and combustible dust atmospheres, the design eliminates potential safety risks at the source during pressure measurement, ensuring a safe production environment.

Corrosion resistance + all-metal sealing for complex media:

The full stainless-steel housing combined with a corrosion-resistant sensing diaphragm effectively withstands hydraulic oil, natural gas, chemical raw materials, and other corrosive media. The gap-free, fully sealed structure achieves an IP65 protection rating, providing effective dust and water resistance for humid and dusty industrial sites.

High accuracy + wide temperature compensation for reliable measurement:

Equipped with a high-quality piezoresistive sensor element, the transmitter offers a combined accuracy of 0.25%FS to 0.5%FS, with linearity error as low as 0.02%FS, ensuring precise and stable measurements. Wide-range temperature compensation enables stable operation with medium temperatures from –10 °C to 70 °C, while the ambient temperature range extends from –40 °C to 125 °C, effectively minimizing the impact of temperature fluctuations on measurement accuracy.

Multiple protection mechanisms for extended service life:

Built-in reverse polarity protection, transient overcurrent and overvoltage protection, and anti-interference circuitry effectively resist electrical disturbances and accidental faults common in industrial environments. The transmitter also withstands overloads up to 150%FS, ensuring that core components remain protected even during sudden pressure spikes, thereby extending product lifespan.

Visual operation for greater convenience:

An optional LCD display provides real-time, intuitive pressure readings without the need for additional display devices. Standard 4–20 mA output enables seamless integration with PLC, DCS, and other industrial control systems for remote monitoring and control.

2. Application Scenarios: Meeting Multi-Industry Pressure Measurement Needs

Thanks to its excellent environmental adaptability and media compatibility, the PT124B-280 series is widely used for fluid pressure measurement and control across various industries. Typical applications include:

Core application fields

- Petrochemical: Pressure monitoring in crude oil pipelines, chemical reactors, and natural gas storage tanks

- Coal mining: Pressure measurement in underground hydraulic systems and gas drainage pipelines

- Power and energy: Boiler steam pressure and hydraulic system pressure control in power generation units

- Hydraulic machinery: Hydraulic pressure feedback for construction machinery such as excavators and tunnel boring machines

Extended application scenarios

- Marine industry: Pressure monitoring of propulsion systems and fuel pipelines

- Building automation: Pressure control in central air-conditioning water circulation systems

- Rubber and plastics processing: High-temperature melt pressure measurement in extrusion equipment (high-temperature models applicable)

- Coal–water slurry boilers: Pressure monitoring of boiler feed pipelines

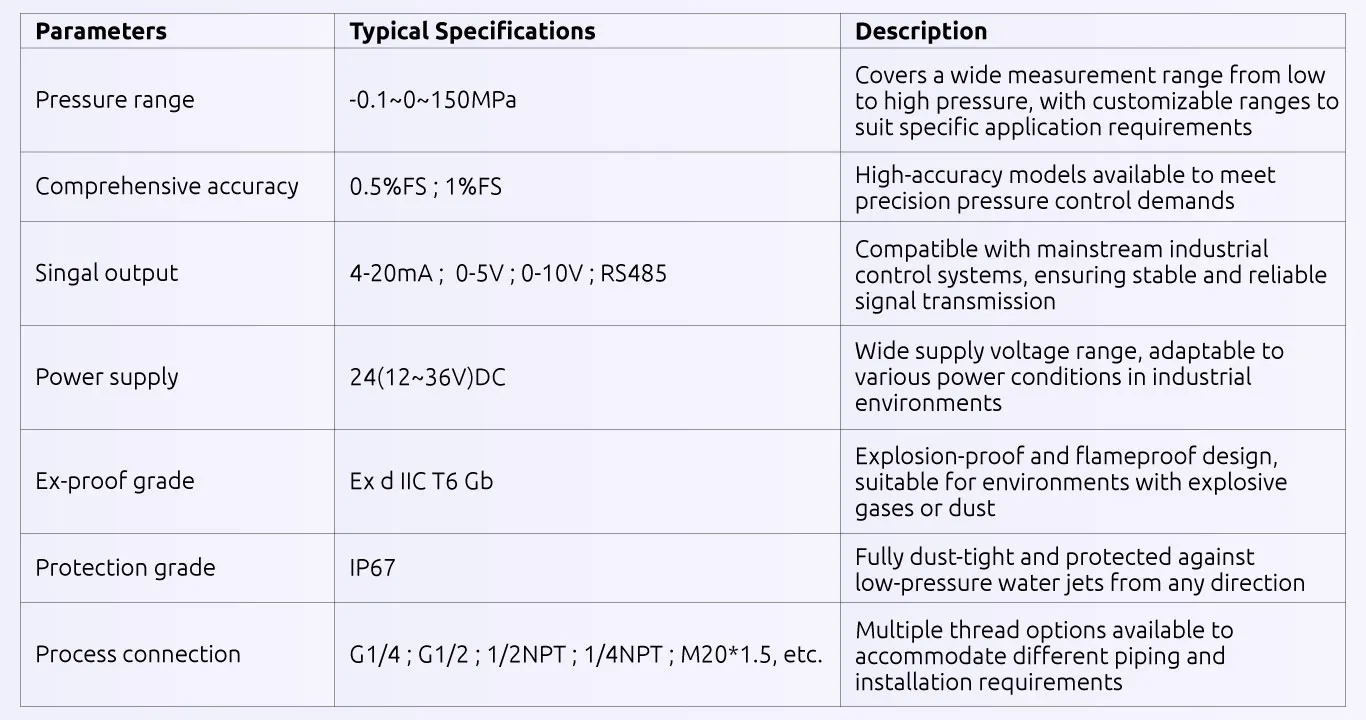

3. Key Technical Parameters: Precisely Matching User Requirements

4. Installation and Operation Guidelines: Proper Use for Longer Service Life

4.1 Pre-installation Preparation

- Inspect the product for any damage, and verify that the model, range, and accuracy class match the order requirements. Keep the product manual and certificate of conformity properly.

- Confirm that the hazardous area classification of the installation environment matches the product’s explosion-proof rating to avoid improper use.

- Check that the mounting port dimensions meet requirements and are free of metal debris, plastic residues, or other contaminants to prevent damage to the sensing diaphragm during installation.

4.2 Installation Guidelines

- Protect the sensing diaphragm carefully during installation to avoid impact or abrasion. The wrench must only be applied to the hexagonal wrench interface; applying force to the housing tube or rear connector is prohibited to prevent internal damage.

- When measuring high-temperature media (such as high-temperature melts), ensure that the sensor probe extends into the high-temperature zone while the housing remains away from heat sources (housing temperature resistance ≤ 80 °C). Brackets may be used to prevent overheating of the housing, which could affect performance.

- Route signal cables separately through cable trays and avoid running them parallel to high-power cables to reduce electromagnetic interference. Follow the wiring diagram strictly, ensure correct polarity, and avoid reverse polarity or overvoltage damage.

4.3 Operation and Maintenance

- Avoid long-term overload operation. It is recommended to keep the working pressure within 0.5–0.8 times the rated range. Although the product can withstand 150%FS overload, prolonged overload will still affect accuracy and service life.

- Periodically check cable connections for looseness, damage, or aging. If the measured medium is prone to crystallization or blockage, clean the pressure port regularly using suitable organic solvents. Do not insert tools or objects into the port for cleaning.

- If abnormal operation occurs, stop the equipment immediately for inspection. Do not disassemble or repair the transmitter yourself (there are no user-serviceable parts). Contact after-sales service personnel promptly.

4.4 Special Application Notes

When used on high-temperature equipment such as extruders, allow sufficient heating time after installation and start measurement only after the material has fully melted. During removal, disassembly should also be carried out at normal operating temperature to prevent material solidification from damaging the sensor and equipment.

5. Selection Recommendations and After-Sales Support

- Select appropriate diaphragm materials and installation methods based on the corrosiveness and temperature of the measured medium (for high-temperature media, choose high-temperature probe versions).

- When defining the measurement range, allow sufficient margin to prevent pressure fluctuations from exceeding the rated range.

- Choose the output signal type according to control system requirements (4–20 mA is the standard choice), and confirm the process connection thread specification.

With its flameproof and explosion-proof design, corrosion resistance, high accuracy, and excellent stability, the ZHYQ PT124B-280 series explosion-proof pressure transmitters are ideally suited for pressure measurement in demanding industrial environments such as petrochemical plants, coal mines, and power generation facilities. Proper selection, installation, and maintenance ensure full utilization of product performance, providing reliable protection for production safety and efficiency.