In the process of oil extraction, transportation and processing, the accurate measurement of gas-liquid two-phase flow plays a key role in production efficiency, cost control and safe production! With the development of the industry, skid-mounted equipment has been widely used in various energy projects due to its integration, modularization, easy transportation and installation.

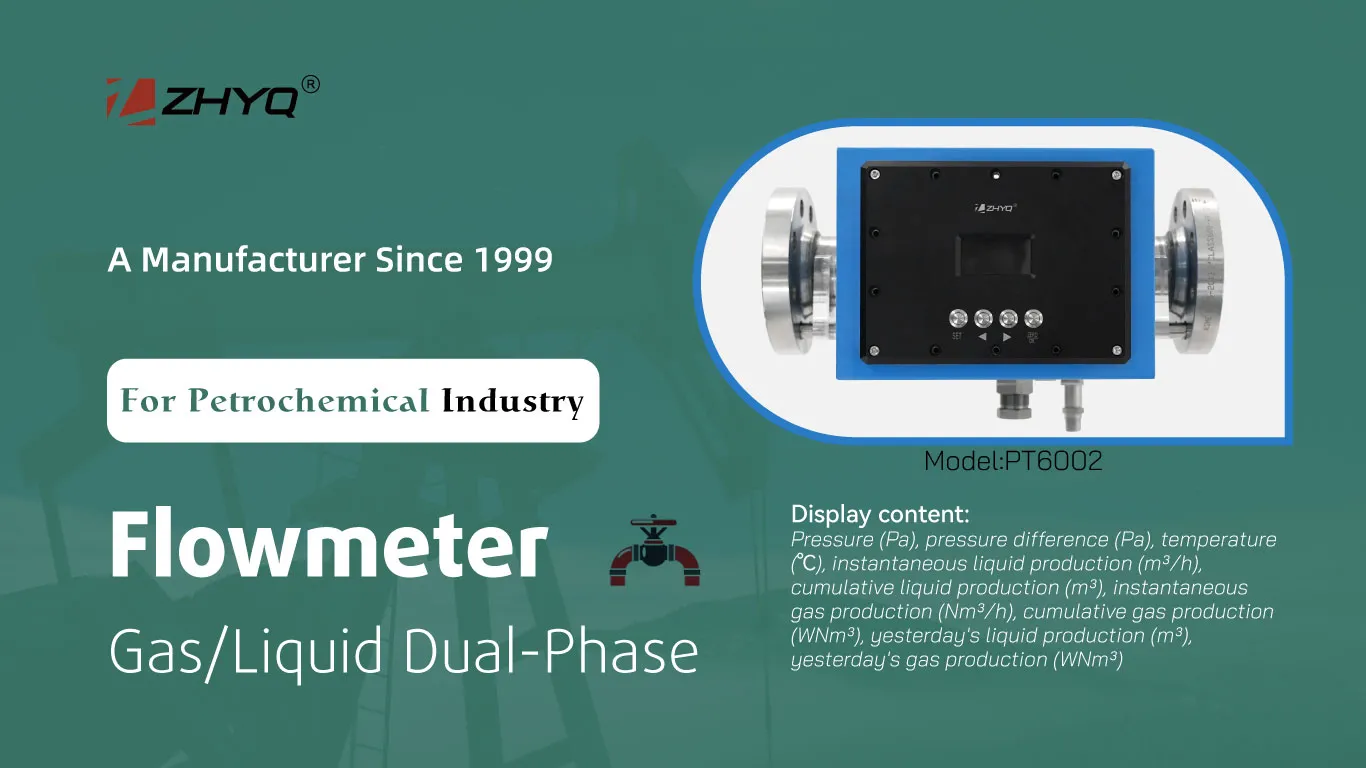

Traditional measurement methods are difficult to meet the requirements of high precision, real-time and compactness. The emergence of gas-liquid two-phase multi-parameter flow meter (PT6002) provides an effective way to solve this problem. It can accurately measure the liquid production, gas production, temperature and other parameters of gas-liquid two-phase flow in the limited space of the skid-mounted equipment , ensuring the efficient and stable operation of the skid-mounted equipment.

1). Separate measurement

Traditional gas-liquid two-phase flow measurement often uses a separation measurement process. The principle is to first use a separator to separate the gas-liquid mixture into a single gas phase and a liquid phase.

1.For the gas phase, orifice flow meters, vortex flow meters, etc. are usually used for flow measurement.

2.For the liquid phase, turbine flow meters, electromagnetic flow meters, etc. are used.

2).Combination measurement of multiple flow meters

For example, combine the Venturi tube with a turbine flow meter. Or use a throttling element with a multi-hole dynamic pressure probe to comprehensively calculate the flow of gas and liquid phases.

1). Problems with separate measurement and metrology processes

2) Problems in the measurement process of multiple flowmeter combinations

Gas/liquid dual phase multi-parameter flow meter integrated into skid mounted system.

The liquid production, gas production and temperature measured by the flow meter are transmitted to the PLC control system of the skid-mounted equipment in real time through the RS485 communication interface or other standard communication protocols. The PLC processes, stores and analyzes these data, and automatically controls the relevant equipment in the skid-mounted equipment, such as pumps and valves, according to the preset control strategy, to achieve optimization and stable operation of the production process. At the same time, the data can also be uploaded to the remote monitoring center through the remote communication module, which is convenient for managers to grasp the operating status of the skid-mounted equipment in real time.

1) High-precision measurement

Compared with traditional measurement processes, the gas-liquid two-phase multi-parameter flow meter directly measures the gas-liquid mixture, avoiding the errors caused by incomplete separation. It also uses advanced sensor technology and precise algorithms to comprehensively consider the impact of multiple factors on the measurement results, greatly improving the measurement accuracy.

2) Strong real-time performance

It can measure multiple parameters of gas-liquid two-phase flow online in real time and quickly reflect the dynamic changes of fluid parameters. In the project, the data update frequency can reach seconds, so that operators can timely grasp the gas-liquid flow in the skid-mounted equipment, respond quickly to abnormal situations in the production process, adjust production parameters in time, ensure the continuity and stability of production, and effectively reduce losses caused by production fluctuations.

3) Compact structure, suitable for skid-mounted equipment

The multi-parameter flow meter has a compact structure design, small size, small space occupation, and does not require a large separator, which greatly saves the internal space of the skid-mounted equipment, facilitates the layout and integration of the equipment, and also reduces the difficulty of equipment installation and commissioning.

4) Easy maintenance

The flow meter has no complicated moving parts inside, which reduces failures caused by component wear, sticking, etc. and reduces maintenance workload.

5) Multifunctional integration

A set of multi-parameter flow meters can replace multiple measuring instruments in traditional processes, reducing the number of equipment and system complexity, reducing equipment procurement costs, while also reducing the connecting pipes and interfaces between equipment, reducing leakage risks, and improving system reliability.

6) Comprehensive utilization of data and production optimization

The multi-parameter data provided can help us better understand the flow characteristics of gas-liquid two-phase flow in skid-mounted equipment and the operating conditions of the production process, providing a strong basis for improving production processes, optimizing equipment performance and rational use of energy.

Shanghai Zhaohui Pressure Apparstus Co.,Ltd. – A comprehensive high-tech enterprise integrating R&D, production, and sales. With products distributed nationwide and exported to over 50 countries and regions, the company achieves annual sales of millions of sensing elements, sensors (transmitters), and control systems.

© 2025 Shanghai Zhaohui Pressure Apparstus Co.,Ltd. All Rights Reserved.

Designed by AdmarV