EVA (ethylene-vinyl acetate copolymer) resin is widely used in many industries. Its core advantages include flexibility, low temperature resistance, chemical resistance, adhesion, transparency, etc. The application scenarios of EVA with different VA contents vary significantly (the higher the VA content, the stronger the flexibility and adhesion, and the lower the hardness and crystallinity).

Foam products (such as shoe materials, cushioning packaging materials, sports and leisure equipment materials, construction/engineering materials, etc.) are one of its largest application areas. The performance of foam products is closely related to the melt pressure during the production process. How to accurately control the melt pressure has become the key to improving product competitiveness, and the application of melt pressure transmitters has gradually received attention.

The performance differences of EVA with different VA contents directly determine its application direction, which can be simply summarized as follows:

| VA content range | Main performance characteristics | Typical application areas |

| 5%~15% | Higher hardness, close to PE, easy to process | Film, wire and cable, pipe |

| 15%~30% | Good flexibility and excellent foaming performance | Foamed shoe materials, cushioning packaging, photovoltaic encapsulation films |

| 30%~40% | Strong viscosity and high elasticity | Hot melt glue, adhesives, toys, erasers |

1.Rely on mechanical pressure gauges or indirect parameters (such as screw torque, main engine current) to estimate melt pressure.

2.Manual regular inspection records, data is discrete and delayed.

Manually adjusting the screw speed, temperature or feed rate based on experience has a slow response speed: lack of real-time pressure feedback closed-loop control, and large process fluctuations.

Mechanical meters are prone to drift, and indirect parameters cannot reflect the true melt state.

Unable to capture sudden changes in pressure in real time, resulting in batch defective products.

uneven cell structure (different sizes, low closed cell rate).

Over-pressure can lead to filter breakdown, die leakage, and even safety accidents.

Poor product consistency and long production change and debugging cycle.

For example, during the foaming process at a shoe material factory, the sudden increase in pressure in the melting chamber was not detected, which caused the cross-linking agent to decompose prematurely, resulting in partial collapse and uneven hardness of the product.

High temperature melt pressure transmitter

1.High temperature and high pressure resistance: temperature resistance > 200°C, pressure resistance > 50MPa (adaptable to EVA foaming process window).

2.Direct contact with melt: The measuring end material is made of hardened stainless steel diaphragm (15-5PH), which is resistant to melt corrosion and wear.

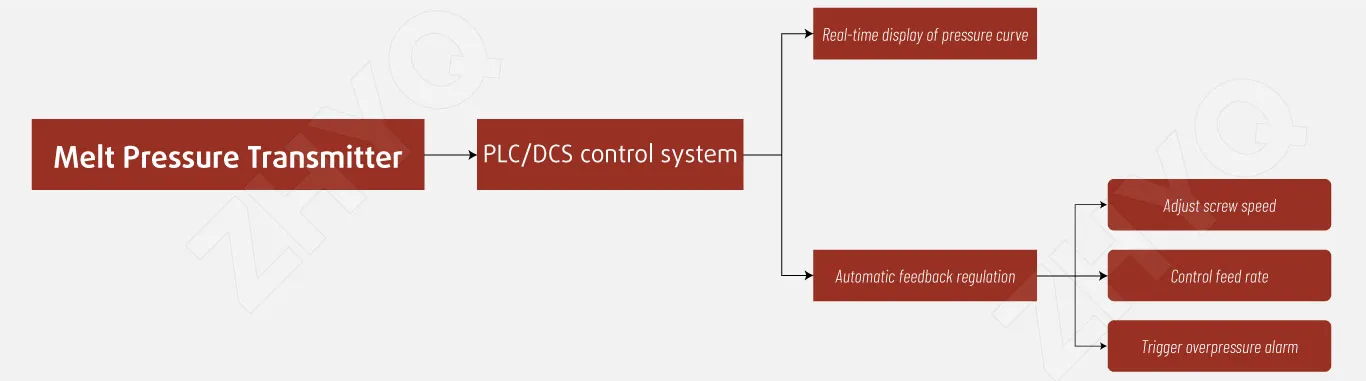

3.Real-time digital signal: 4~20mA or digital bus (such asCANopen) output, millisecond response.

4.Integrated installation: Thread or flange installed in the confluence section of the extruder, die head or foaming mould cavity.

| Traditional pain points | Solution advantages | Benefits |

| Pressure monitoring is not accurate | Directly measure the actual melt pressure, error <±0.5%FS | Improved cell uniformity, density deviation ≤ 3% |

| Response Delay | Capture sudden pressure changes in milliseconds and adjust them automatically | Reduce scrap rate by more than 30% |

| Equipment overload risk | Set the pressure threshold, automatically shut down or release the pressure in case of overload | Avoid unplanned downtime and protect critical equipment |

| The process relies on manual labor | Data traceability supports digital management of process parameters | Reduce production changeover time by 50% and accelerate new product development |

| Waste of energy | Stable pressure = stable flow, reduced reactive power consumption | Energy consumption reduced by 8%~12% |

Shanghai Zhaohui Pressure Apparstus Co.,Ltd. – A comprehensive high-tech enterprise integrating R&D, production, and sales. With products distributed nationwide and exported to over 50 countries and regions, the company achieves annual sales of millions of sensing elements, sensors (transmitters), and control systems.

© 2025 Shanghai Zhaohui Pressure Apparstus Co.,Ltd. All Rights Reserved.

Designed by AdmarV