In the process of crude oil extraction, the output of oil wells is usually a mixture of oil, gas and water , mixed with other mixtures such as sand, paraffin, sulfur, etc. As the extraction time goes by, the proportion of each phase will continue to change, and the impurity content will also be different . Accurately grasping the production information of each phase of oil, gas and water is the key basis for formulating oilfield development plans, dynamic production monitoring, reservoir evaluation and improving extraction efficiency.

As oil fields enter the medium-to-high water content development stage, the composition of oil well output has become more complex, and traditional metering methods can no longer meet the high-precision, real-time metering needs. At the same time, in order to achieve refined mining and reduce costs and increase efficiency, oilfield companies have increasingly higher requirements for multi-parameter flow meter technology, and are in urgent need of an advanced metering device that can simultaneously measure multiple parameters of oil, gas and water.

Traditional oil, gas and water metering mainly uses the separation metering method. This process requires the use of a separator to separate oil, gas, water and impurities , and then a single-phase flow meter is used to measure each parameter.

The specific process is as follows: the oil, gas and water mixture produced by the oil well first enters the separator, where the oil, gas and water are separated by gravity sedimentation, centrifugal separation, etc. The separated natural gas enters the gas flow meter for metering, the separated crude oil enters the liquid flow meter for metering, and the water is metered by another metering device, and the impurities are collected and discharged .

In addition, some oil fields use intermittent metering to estimate the production of oil, gas and water by regularly sampling and analyzing the output of oil wells and combining empirical formulas.

Although the separation metering method has relatively good accuracy, its operability is relatively poor, it takes a long time, has high requirements for equipment, and the volume of the equipment is relatively large; the time required for crude oils of different viscosities is different.

In traditional processes, it takes a certain amount of time from the mixture entering the separator to the completion of the metering of each phase. It is impossible to reflect the dynamic changes of the oil well output in real time, and it is impossible to respond to sudden situations in the oil well in time, which is not conducive to production regulation

Separators and other equipment are large in size and require a large site space, which increases the difficulty and cost of equipment layout, especially in places with limited space such as offshore oil fields.

The separator is prone to scaling and corrosion, and needs to be cleaned and repaired regularly. In addition, related auxiliary equipment such as pumps and valves are also prone to failure, which increases the maintenance workload and cost of the equipment.

The separation process requires a certain amount of energy to maintain the operation of the separator. At the same time, the operation of each single-phase flow meter also requires energy support, resulting in high overall energy consumption.

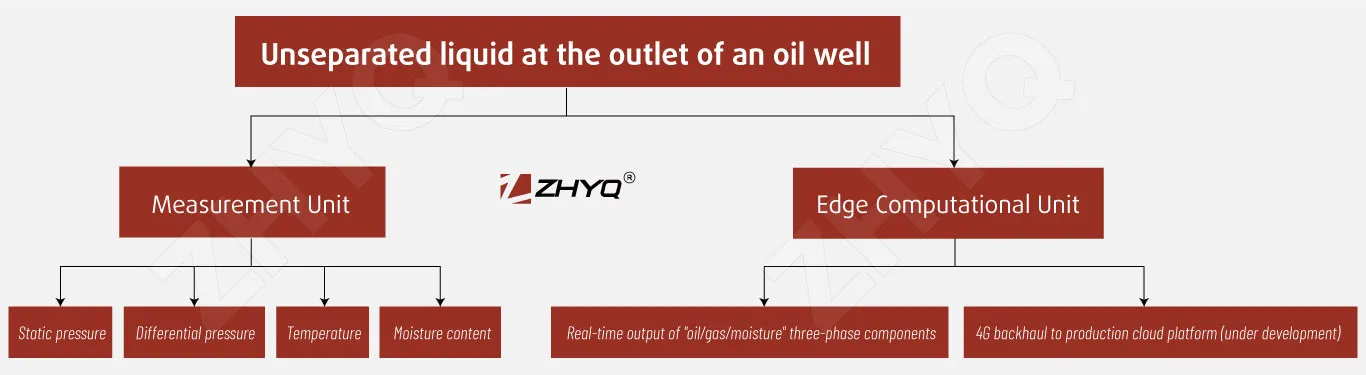

The “oil, gas and water 3-phase multi-parameter flowmeter” was selected and installed on the pipeline at the wellhead of the oil well to directly measure the oil, gas and water mixture produced by the oil well online. The flowmeter can measure the total flow and flow rate of the mixture; it can monitor the water content in the liquid phase in real time; at the same time, combined with temperature and pressure sensors, it can measure multiple parameters such as differential pressure, pressure, temperature, flow, etc. of each phase of oil, gas and water

The oil, gas and water multi-parameter flow meter does not need to separate the oil, gas and water mixture, and can directly measure the parameters of each phase, avoiding the error caused by incomplete separation. The advanced sensing technology and algorithm it adopts can effectively cope with complex flow pattern changes, and the measurement accuracy can reach within ±3%FS, greatly improving the accuracy of measurement.

The flow meter can output measurement data in real time, which can promptly reflect the dynamic changes of oil well output, provide a fast and accurate basis for oil field production control, facilitate timely adjustment of mining strategies and improve production efficiency.

Compared with traditional separation and metering equipment, the oil, gas and water multi-parameter flow meter has a compact structure, small size, and easy installation, which greatly saves site space.

The flow meter has no complicated separation components, which reduces equipment failures caused by scaling, corrosion, etc. and reduces maintenance workload.

No separator or other equipment is required for operation. Only the flow meter itself consumes a small amount of energy, which is beneficial for oilfield enterprises to achieve energy conservation, emission reduction, cost reduction and efficiency improvement.

The supporting data collection and transmission system realizes the automatic collection, storage and analysis of metering data, provides strong support for the digital and intelligent management of oil fields, and helps to improve the overall management level of oil fields.

Shanghai Zhaohui Pressure Apparstus Co.,Ltd. – A comprehensive high-tech enterprise integrating R&D, production, and sales. With products distributed nationwide and exported to over 50 countries and regions, the company achieves annual sales of millions of sensing elements, sensors (transmitters), and control systems.

© 2025 Shanghai Zhaohui Pressure Apparstus Co.,Ltd. All Rights Reserved.

Designed by AdmarV