In chemical fiber spinning production, melt pressure transmitters play a key role in improving production stability, product quality and process controllability by monitoring melt pressure in real time and feeding back to the control system.

The chemical fiber textile industry is one of the most widely used fields for melt pressure transmitters. With the development of the chemical fiber textile industry, enterprises have continuously improved their requirements for precise control of the production process. As a key device for monitoring pressure changes in equipment such as spinning machines, the demand for melt pressure transmitters will continue to rise!

With the application of technologies such as the Internet of Things, big data, and artificial intelligence in the chemical fiber textile industry, melt pressure transmitters are also developing in the direction of intelligence.

1. Melt pressure stability: Pressure fluctuations will lead to uneven fiber thickness (if the deviation is greater than 1%, it will affect the quality), which needs to be monitored in real time by a pressure transmitter (such as a high-temperature melt pressure sensor) and fed back to the extruder speed adjustment.

2. Temperature uniformity: The temperature deviation of the melting section must be less than ±1°C, otherwise the polymer is prone to degradation or solidification, and the equipment needs to use a multi-layer heating jacket + PID temperature control system.

Using 4-20mA current signal or HART protocol (strong anti-interference ability), with shielded cable (double-layer aluminum foil + braided mesh), the accuracy is <0.1% when the transmission distance is ≤100m.

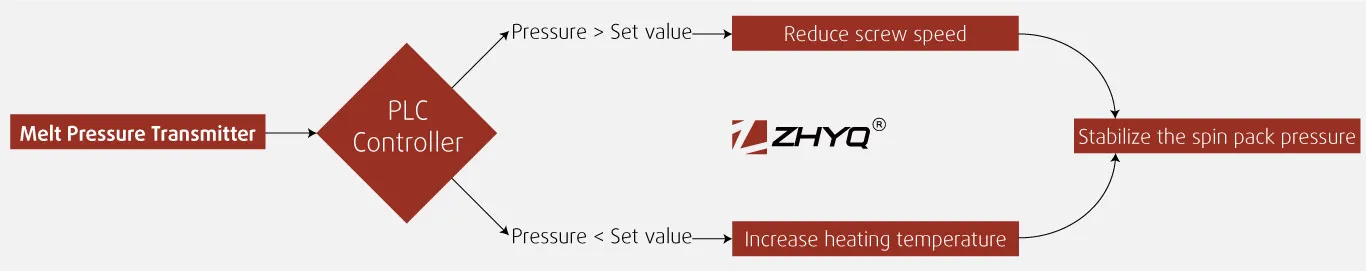

Dynamically adjust melt pressure stability

Real-time acquisition of melt pressure (accuracy 0.1-0.5% FS), linkage adjustment of screw speed or melt pump frequency; when slice viscosity changes, automatic compensation of pressure parameters to avoid manual adjustment lag.

From “post-detection” to “pre-control”

Automatic alarm and linkage speed reduction when the set pressure threshold is exceeded; storage of pressure-time curve for easy tracing of quality problems.

Reduce the risk of loss and failure of key components

Dual benefits of energy saving and consumption reduction and efficiency improvement

Open the key nodes of intelligent production

Shanghai Zhaohui Pressure Apparstus Co.,Ltd. – A comprehensive high-tech enterprise integrating R&D, production, and sales. With products distributed nationwide and exported to over 50 countries and regions, the company achieves annual sales of millions of sensing elements, sensors (transmitters), and control systems.

© 2025 Shanghai Zhaohui Pressure Apparstus Co.,Ltd. All Rights Reserved.

Designed by AdmarV