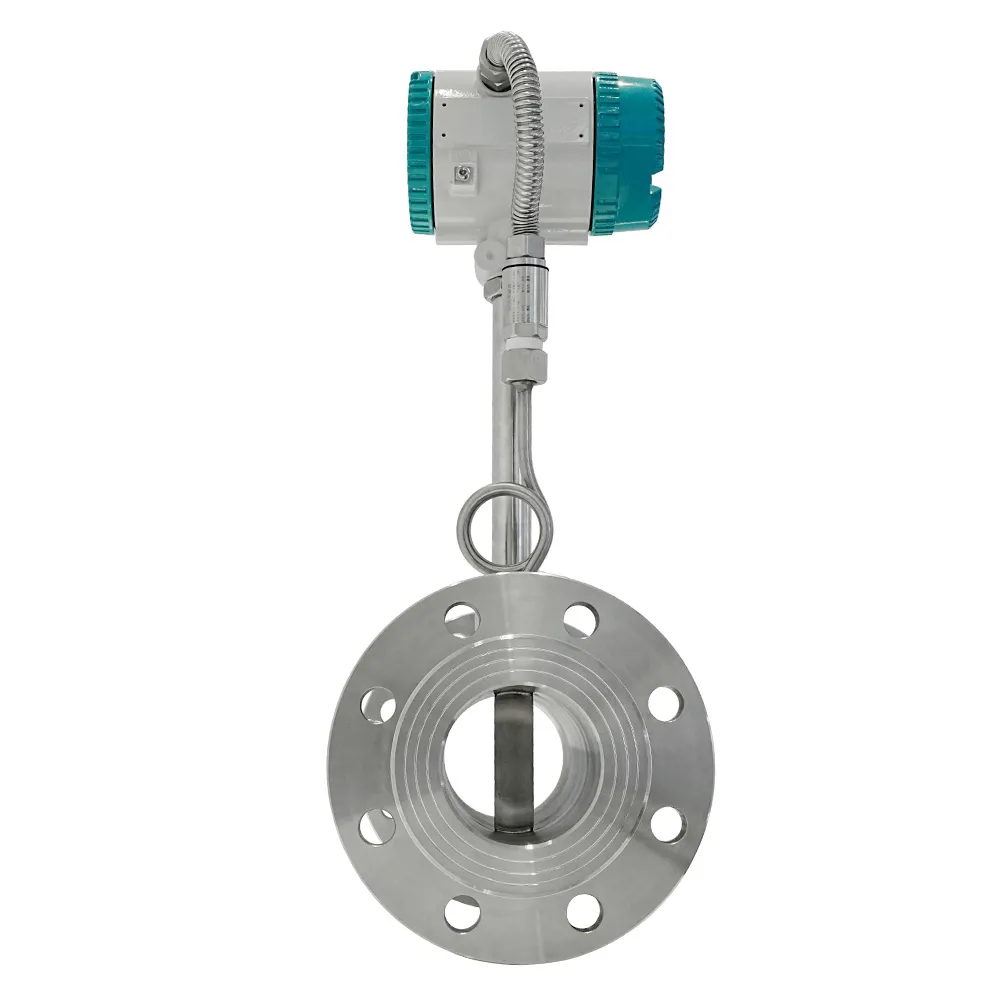

Description

Technical Parameters

| Nominal diameter(mm) | DN15~DN300 (Claming connection) | ||

| DN15~DN500 (Flange connection ) | |||

| Measuring medium | Liquid; Gas; Steam | ||

| Measuring range | Liquid; 0.35~7.0m/s; Gas; 5.0~60.0m/s; Steam; 6.0~70.0m/s | ||

| Pressure(MPa) | 1.6、2.5、4.0、6.3 (customizable) | ||

| Medium temperature | Standard temp; -40~+150℃ | ||

| Medium temp; -40~+250℃ | |||

| High temp; -40~+350℃ | |||

| Material | SS304 ; SS316 ; SS316L (customizable) | ||

| Accuray | 1.0%FS ; 1.5%FS | ||

| Repeatability | ≤±0.33% | ||

| Range ratio | 1; 10 ~ 1; 20 | ||

| Converter | Type | Intergrated Type ; Split Type ; Temp.&Pressure Compensation Type | |

| Power supply | 12VDC/24VDC ; Battery | ||

| Display type | LCD display | ||

| Telecommunication | HART ; Modbus RS485 | ||

| Signal output | Three wires ; Two wires(4-20mA) | ||

| Ex-proof grade | Intrinsically safe ex-proof Exia Ⅱ CT6FGa | Flameproof Exd Ⅱ CT6Gb | |

| Protection | IP65 ; IP67 ; IP68 | ||

| Electrical connection | M20*1.5 ; 1/2NPT | ||

| Ambient condition | Temp. | -30 ~ 60℃ | |

| Humidity | 5% ~ 90% | ||

| Air pressure | 86 ~106kPa | ||

Features

1.With a sophisticated low-power LCD display, the local display shows instantaneous flow, cumulative flow, frequency, pressure, temperature, density, current, percentage etc .

2.Probe used four piezoelectric ceramic technologies to effectively eliminate the influence of external vibration on the measurement

3.No moving parts, no wear, no mechanical maintenance and long service life

4.The probe and signal converter are universally interchangeable

5.Split type signal converter can be used, the cable can be up to 10 meters long.

6.Output 4-20mA current signal / pulse signal, or Modbus RS485 signal

7.Two types of intrinsic safety explosion-proof; Exia II CT6Ga; flameproof; Exd II CT6Gb

8.With HART–Protocol communication protocol, Modbus RS485 interface.

Application

1. Industrial processes; steam, natural gas, and water flow measurement in petrochemical, electric power, metallurgy and other industries.

2. Urban utilities; flow monitoring of heating pipe networks and tap water pipes.

3. Energy metering; natural gas trade settlement, factory energy consumption statistics.

4. Environmental protection; flow monitoring in wastewater treatment.