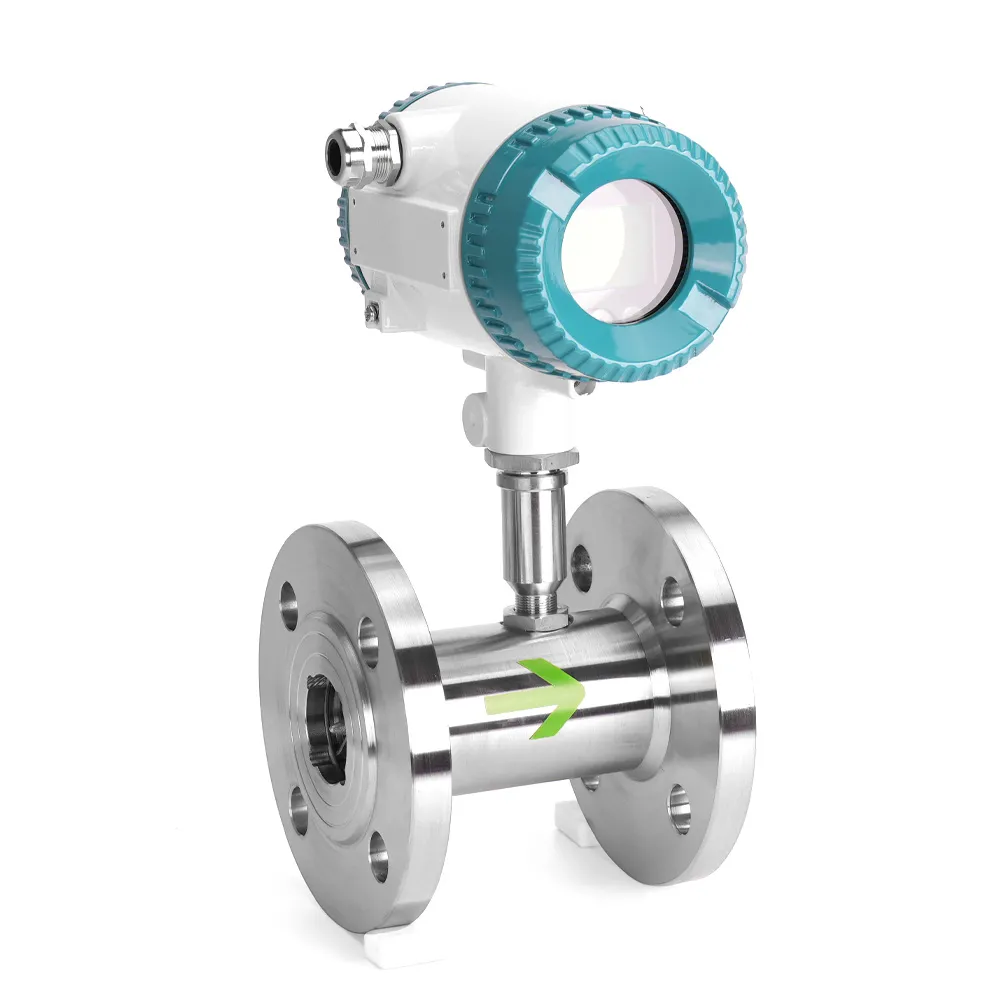

Description

Technical Parameters

| Diameter and connection (mm) | Thread; 4、6、10、15、20、25、32、40 |

| Flange; 15、20、25、32、40、50、65、80、100、125、150、200 | |

| Accuracy | ±1%R ; ±0.5%R ; ±0.2%R(Need to be customized) |

| Range Ratio | 1; 10;1; 15;1; 20 |

| Material | SS304、SS316、SS316L |

| Medium temperature | -20~120℃ |

| Environmental conditions | Temperature; -10~+55℃, relative humidity; 5%~90%, atmospheric pressure; 86~106Kpa |

| Power supply | Sensor; +12VDC ; +24VDC(optional) |

| Transmitter; +24VDC | |

| On-site display type; 3.2V battery | |

| Output | Sensor; Pulse frequency signal, low level ≤ 0.8V, high level ≥ 8V |

| Transmitter; 4 ~ 20mA(2-wires) | |

| Signal transmission cable | STVPV3×0.3(3-wires),2×0.3(2-wires) |

| Transmission distance | ≤1000m |

| Signal cable interface | Basic type; Hirschmann connector ; Ex-proof type; Internal thread M20*1.5 |

| Ex-proof grade | Basic type; Non-ex-proof product ; Ex-proof type; ExdIIBT6 |

| Protection grade | IP65 |

Features

1. High accuracy, usually the accuracy can reach ±1%R, ±0.5%R, and the high accuracy type can reach ±0.2%R

2. Good repeatability, suitable for precise measurement.

3. Fast response speed, can measure pulsating flow

4. Wide range ratio; medium and large diameter can reach 1; 20, small diameter is 1; 10

5. Compact structure, small size, easy installation, small pressure loss.

6. Output pulse signal, easy to digitalize and transmit remotely, can be directly connected to computer system.

Application

1. Oil and gas; trade measurement of crude oil, refined oil and natural gas (such as gas stations and oil pipelines).

2. Chemical and pharmaceutical; flow control of medium and low viscosity liquids (such as solvents and medicines).

3. Energy and power; flow monitoring of steam turbine lubricating oil and hydraulic oil.

4. Aerospace; precision flow measurement of fuel oil, oxidant, etc.