Description

Technical Parameters

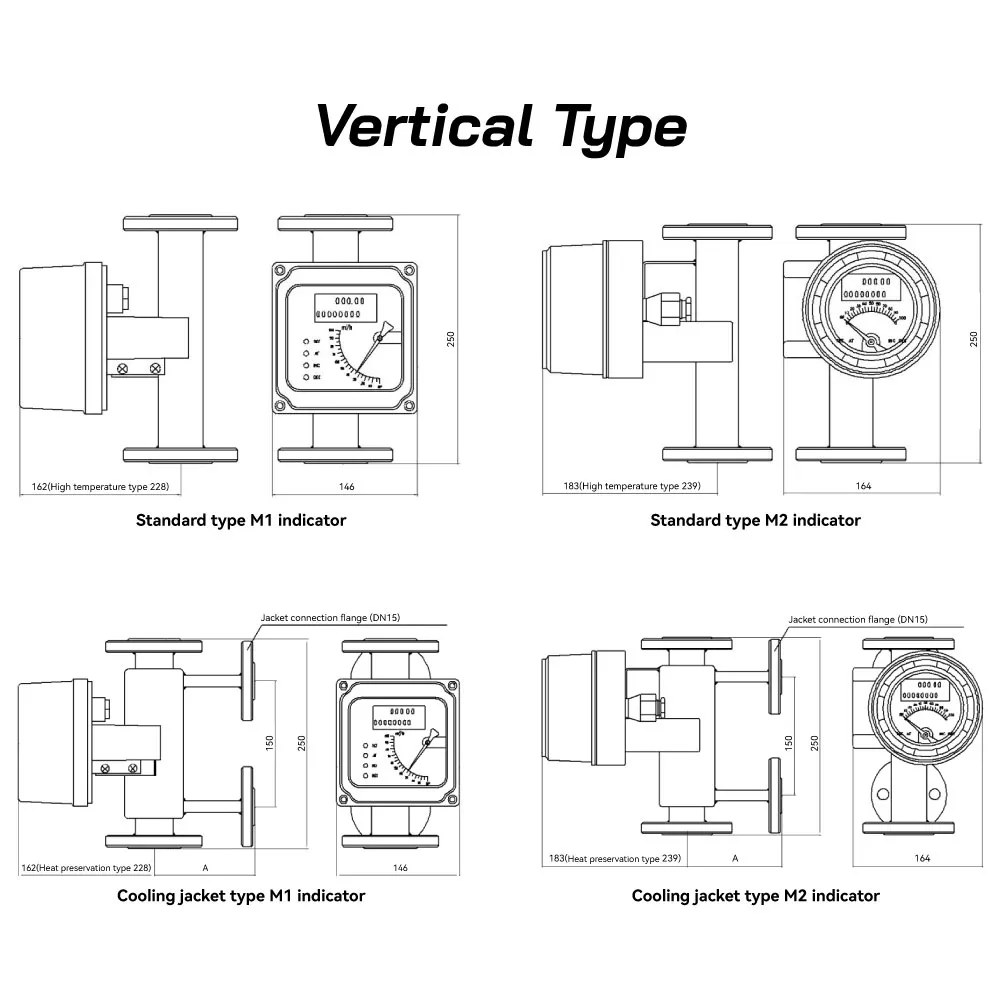

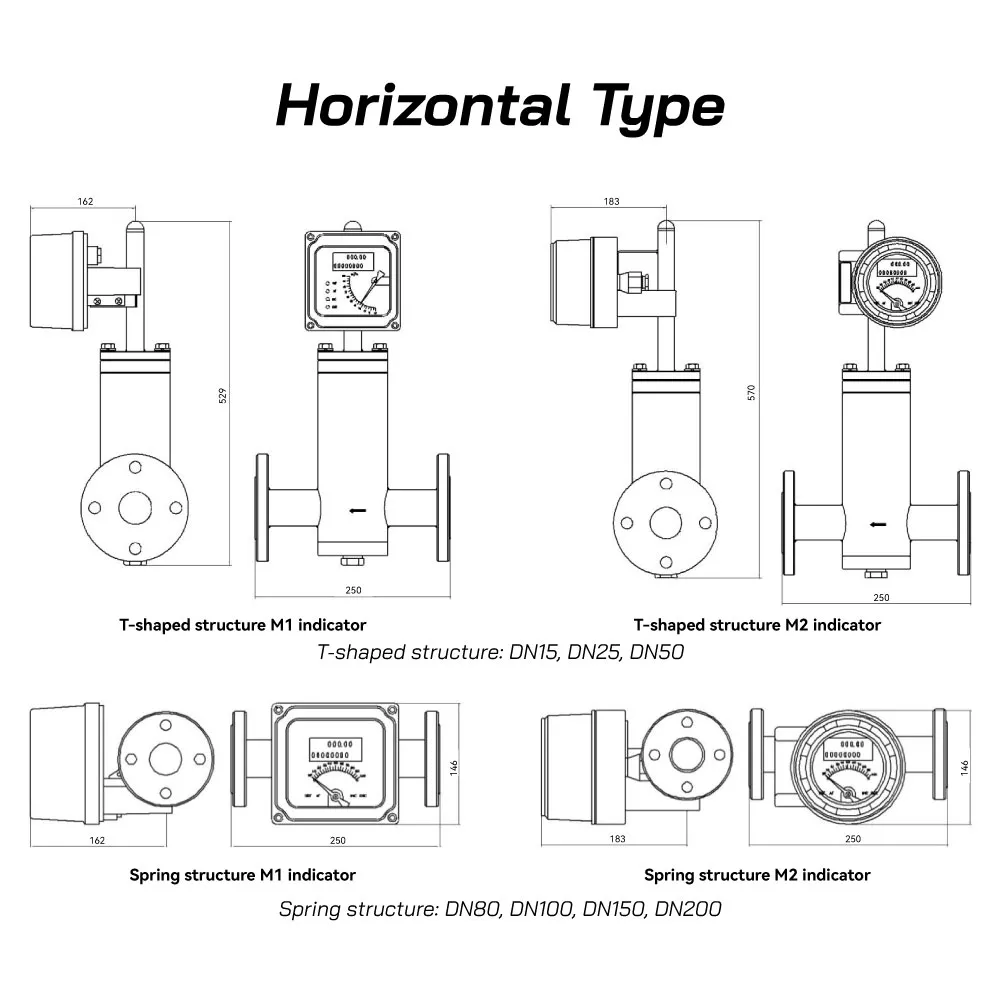

| Flange diameter | DN15 ; DN25 ; DN50 ; DN80 ; DN100 ; DN150 (customizable) |

| Flow range | Water:10~150000l/h ; Gas: 0.5~3000m3/h |

| Range ratio | 10:1 ; 20:1 (Special customization) |

| Accuracy | 1.5%FS ; 1.0%FS (Special customization) |

| Operating pressure | 4.0MPa (Max 20MPa):DN15, DN25, DN50 |

| 1.6MPa [Max (DN80: 10MPa) ; (DN100:6.4MPa) ; (DN150: 4.0MPa)]:DN80, DN100, DN150 | |

| Medium temperature | Standard:-30℃~+120℃ ; high temperature: 120℃~350℃ |

| Power Supply | 24VDC (12~36VDC) ; 220VAC |

| Signal output | 4 ~ 20mA (2-wire), HART protocol can be added |

| Output load | 500Ω(at 24V power supply) |

| Ambient temperature | Local type:-40℃~120℃ ; Remote type: -30℃~60℃ |

| Storage condition | Temperature:-40℃~85℃ ; Humidity: ≤ 85% |

| Electrical Connection | M20*1.5, 1/2 NPT |

| Protection grade | IP65 |

| Explosion Proof | Intrinsically Safe:Ex ia IICT6 ; Flameproof: Ex d IICT6 |

| Medium viscosity | DN15:η<5mPa.s ; DN25: η <250mPa.s ; DN50~DN150: η<300mPa.s |

| Wetted material | SS304 ; SS316 ; SS316L ; Ti ; Teflon lined |

Features

1.Suitable for small-diameter and low-flow medium flow measurement

2.Reliable operation, low maintenance and long service life

3.Low requirement for straight pipe section

4.Wide range ratio 10:1

5.Dual-line LCD display, local instantaneous/accumulated flow display

6.Full metal structure, suitable for high temperature, high pressure and strong corrosive media

7.Non-contact magnetic coupling drive

8.Can be used in flammable and explosive dangerous occasions

9.Optional DC power supply or battery power supply

10.With data recovery, data backup and power-down protection functions

11.Multi-parameter calibration function

Application

1. Chemical and petrochemical: Measure the flow of various acids, alkalis, solvents, reaction raw materials, intermediate products, finished oil, etc.

2. Oil and gas: Measure wellhead fluids, natural gas, liquefied gas, oil products, oilfield chemical injection, etc.

3. Electricity: Measure boiler feed water, condensate, chemical water treatment, fuel oil, lubricating oil, etc.

4. Pharmaceutical and bioengineering: Measure pure water, water for injection (WFI), clean steam, process gas, liquid medicine, etc. in process steps that require metal materials and good sealing

5. Food and beverage: Measure water, juice, milk, beer, edible oil, syrup, steam, CIP/SIP fluid, etc.

6. Water treatment and environmental protection: Measure raw water, treated water, sewage, chemical additives.

7. HVAC: Measure chilled water, cooling water, heat transfer medium, compressed air, etc.

8. General industry: Compressed air system, cooling circulation system, process cooling water, inert gas protection, fuel distribution, etc.