History of Piezoresistive Sensors:

In 1954, C.S. Smith discovered the piezoresistive effect of silicon and germanium, which states that when an external force is applied to a semiconductor material, its resistance changes significantly.

From the 1960s to the 1970s, silicon diffusion technology advanced rapidly. Technicians diffused strain resistors directly onto a silicon crystal surface, selecting the appropriate crystal orientation. The back surface was then processed into a concave shape, forming a thinner silicon elastic membrane known as a silicon cup.

From the 1970s to the 1980s, anisotropic silicon etching techniques were applied based on the silicon cup diffusion theory. The fabrication process for diffused silicon sensors, primarily based on anisotropic silicon etching, evolved into anisotropic silicon processing technology capable of automatically controlling silicon membrane thickness.

With the advancement of technology, micromachining has now enabled the computer-controlled fabrication of structural pressure sensors with dimensions controlled within the micron range. This technology allows the fabrication and etching of micron-scale grooves, strips, and membranes, bringing pressure sensors into the micron realm.

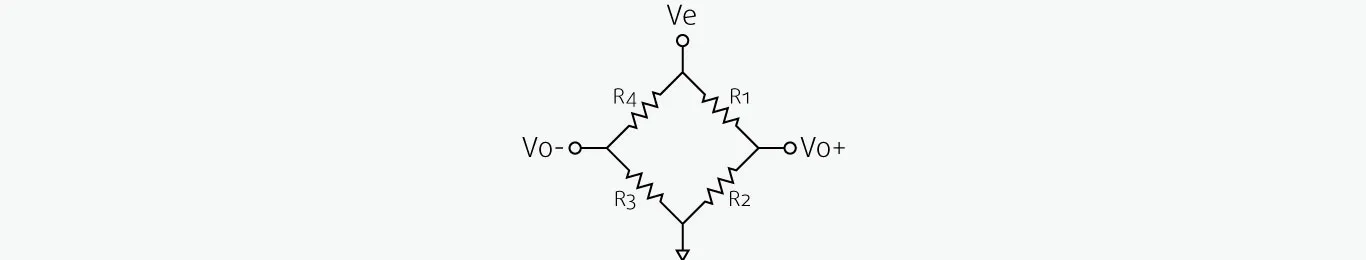

Piezoresistive sensor principle:

The figure below shows a basic Wheatstone bridge circuit. The bridge output, Vo, is the differential voltage between Vo+ and Vo-. When using the sensor, as pressure changes, the resistance of one or more resistors changes due to the piezoresistive effect. This change in resistance causes a change in the output voltage.

Basic Wheatstone Bridge Block Diagram

Vo = Ve(R2/(R1 + R2) – R3/(R3 + R4))

Since 1999, ZHYQ has been focusing on the research and development and production of core technologies for sensor cores. It provides core components such as differential pressure cores, diffused silicon cores, and micro-fuse cores for sensors in China, the United States, the Middle East, Italy and other countries. It also shares experience and data from industry applications with customers, and has high competitiveness in technology and price.

Monocrystalline silicon pressure core:

When molten silicon solidifies, silicon atoms form numerous nuclei arranged in a diamond lattice. When these nuclei grow into grains with uniform crystal plane orientation, they form single-crystal silicon. Due to its uniform internal structure, single-crystal silicon exhibits superior mechanical, optical, and thermal properties. zhyq single-crystal silicon pressure cores feature high precision and excellent stability.

Diffused Silicon Pressure Core:

Traditional silicon semiconductor materials are carved from polycrystalline silicon using micromachining technology. The technology is mature and the process is stable. While it cannot match the precision of single-crystal silicon, it has unique advantages in cost, versatility, and cost-effectiveness.

Glass Micro-Melting Pressure Core:

This innovative technology, developed by the California Institute of Technology in 1965, features a chamber backside constructed of high-temperature glass powder sintered onto 17-4PH low-carbon steel, with the chamber housing constructed of 17-4PH stainless steel. This makes it suitable for high-pressure overloads and effectively resists transient pressure shocks. It can measure fluids containing minimal impurities without the need for oil filling or an isolation diaphragm. Its stainless steel construction eliminates O-ring seals and eliminates the risk of thermal shock. It can measure pressures up to 600 MPa (6000 bar) at high pressures with a maximum accuracy of 0.075%.

However, glass micro-melted sensors present difficulties in measuring small ranges, typically above 500 kPa.

MEMS (micro-electromechanical systems) pressure sensors utilize silicon strain gauges fabricated using a micro/Nanostone bridge. They offer high output sensitivity, stable performance, reliable mass production, and excellent repeatability.