With the continuous deepening of intelligent construction in the coal industry, various types of mining monitoring instruments are playing an increasingly important role in ensuring safe production in coal mines.

Mining pressure transmitters are core components of coal mine safety production monitoring systems. They are mainly used to monitor the pressure values of key parts such as mine pipelines, hydraulic systems, and gas extraction equipment in real time, and output standard signals in real time to provide core data support for mine safety operation, equipment protection, and intelligent control.

Main application scenarios

- Mine-wide Pressure Monitoring: Used to monitor static and dynamic pressure changes in the mine in real time to ensure structural stability during mining.

- Roof Delamination Safety Monitoring: Combined with a roof delamination meter, this system detects the risk of rock separation and prevents collapse accidents.

- Pipeline and Hydraulic System Monitoring: Measures pressure in mine pipelines and hydraulic equipment to optimize fluid flow efficiency and prevent overloads.

- Gas Extraction Equipment Assurance: Designed specifically for explosive environments, this system monitors pressure in gas extraction systems to reduce the risk of gas leaks or explosions.

- Tunnel Pressure Sudden Change Detection: Deployed in tunnel areas, this system provides timely warnings of pressure anomalies to prevent localized collapses.

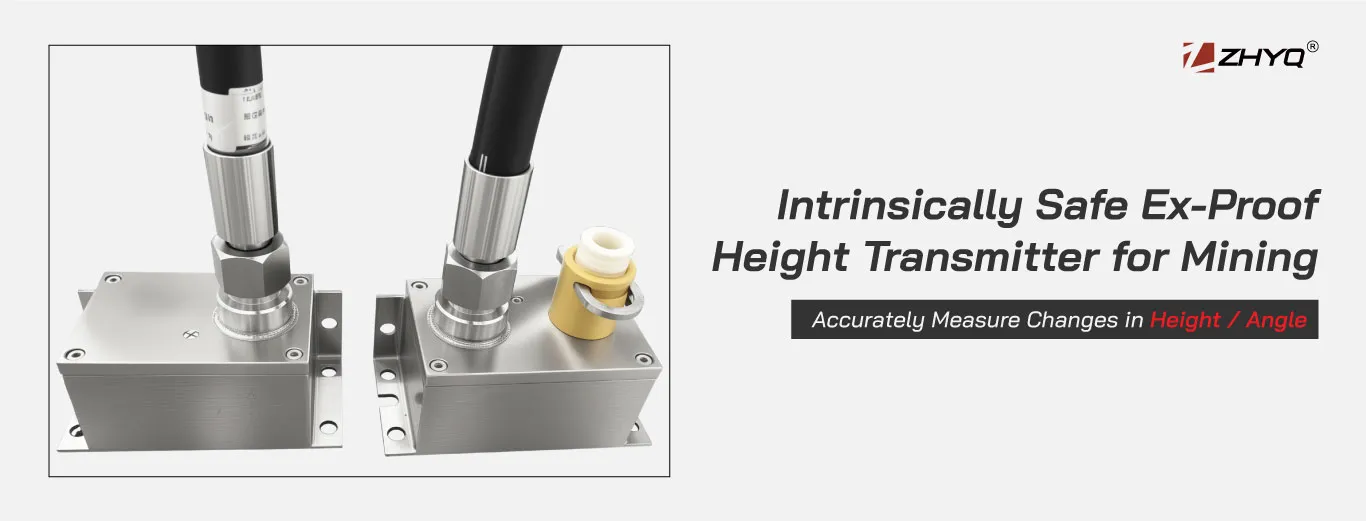

The GUC10(Q) intrinsically safe ex-proof height transmitter for mining applications utilizes a highly accurate, sensitive, and stable sensor and amplifier circuitry in an integrated design. Equipped with a coal mine safety-certified rubber hose, the transmitter’s backpressure chamber is connected to the atmosphere, ensuring that measured height is unaffected by atmospheric pressure. A built-in dual-axis inclination sensor monitors angle deviation in real time and outputs an industry-standard RS485 signal. It is primarily used for monitoring deformation and displacement of hydraulic supports.

The Mine intrinsically safe integrated vibration & temperature sensor is specifically designed for measuring temperature and vibration in mining environments. Its intrinsically safe design makes it suitable for use in explosive environments like mines. Its temperature measurement range of 0-120°C meets various temperature monitoring needs in mines. Its velocity measurement performance of ±3% FS accurately monitors the vibration of mining equipment. Its 4-20mA signal output facilitates integration with other equipment, ensuring long-term stable operation in harsh environments.

Key application scenarios:

- Belt Conveyor: Drive roller bearing vibration and motor temperature to prevent belt breakage caused by bearing seizure.

- Coal Shearer/Tunnel Boring Machine: Cutting unit vibration and hydraulic system temperature to warn of severe vibration caused by tool wear.

- Underground Pump Station: Pump impeller vibration and seal temperature to prevent bearing overheating, leakage, or pump shutdown.

- Ventilation System: Fan blade vibration and motor winding temperature to prevent blade imbalance and mechanical resonance.

Mining pressure transmitters, height transmitters, and integrated temperature & vibration sensors, as key components of the coal mine safety monitoring system, contribute to a comprehensive safety network encompassing environmental safety, mining accuracy, and equipment health. The widespread use of these intelligent monitoring devices has not only significantly improved coal mine safety but also laid a solid foundation for high-quality development in the coal industry. With technological advancements and increasing application, these devices will play an even more critical role in building intrinsically safe mines.