Introduction: In the construction of intelligent mines, accurate data perception is the cornerstone of safety and efficiency. Our company’s intrinsically safe height transmitter integrates height and angle measurement. Its excellent performance improves the safety perception of underground hydraulic supports, helping coal mines achieve safer and more intelligent mining operations.

Deep underground in coal mines, is the hydraulic support height accurate? Is the equipment stable? These seemingly minute data points are directly related to life safety, production efficiency, and equipment lifespan.

Traditional measurement methods often suffer from large errors, low efficiency, and the inability to monitor in real time. To address this industry challenge, our company has dedicated itself to research and development and launched this significant intrinsically safe height transmitter (GUC10). Its excellent performance has become a key enabler for intelligent underground measurement.

Features 1: One instrument with multiple uses

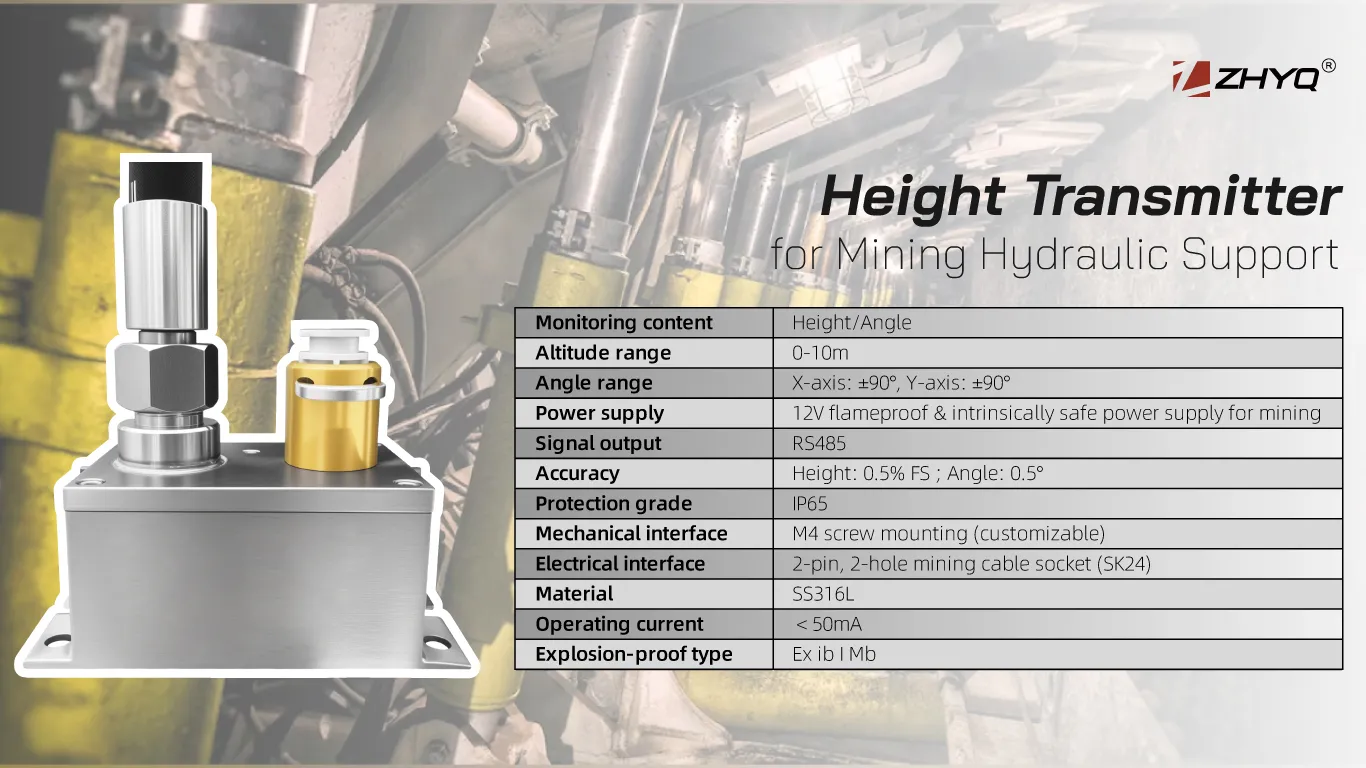

- High-Precision Height Measurement: Utilizing advanced sensing technology, this instrument accurately measures the height of hydraulic supports and other equipment in real time. Data is uploaded to the control system in real time, providing core data support for automatic follow-up support movement and mining height control, ensuring consistent support effectiveness.

- Angle Monitoring: A built-in high-precision inclination sensor simultaneously monitors changes in the tilt, pitch, and other angles of the equipment. This provides real-time visibility into the posture of hydraulic supports, conveyors, and other equipment, effectively providing early warning of risks such as collapse, jamming, and slippage, thus preventing them from occurring. This dual-function device significantly reduces the number of sensors deployed underground, reducing system complexity and maintenance costs.

Features 2: Intrinsically Safe Design with Certification

- The Mining Product Safety Mark (MA Mark) issued by a national authority serves as a “pass” for access to coal mines.

- Meets Ex ia I Ma or Ex ib I Ma intrinsically safe explosion-proof rating requirements for mining applications.

This fundamentally eliminates the risk of spark explosions caused by flow monitoring equipment, providing a solid guarantee for the safety of miners and mine facilities.

Features 3: Rugged and Durable, Stable Performance

- Industrial-Grade Quality: Made from high-quality materials and industrial-grade components, rigorously tested for high and low temperatures, vibration, and shock, this ensures long-term stable operation in the complex underground electromagnetic environment and harsh climate conditions, with an extremely low failure rate.

- Easy Installation: Its compact design and standardized interfaces enable quick integration with hydraulic support electro-hydraulic control systems or other equipment, making deployment a breeze.

Typical Applications

- Intelligent fully mechanized mining face: Core instrument for hydraulic support posture monitoring and automatic control.

- Tunnel support monitoring: Monitors roadway roof delamination and deformation convergence.

- Equipment posture monitoring: Used for tilt alarms and protection of equipment such as belt conveyors and monorail cranes.