In the delicate and demanding field of fiber material production, we are constantly searching for the key player that ensures quality and efficiency.

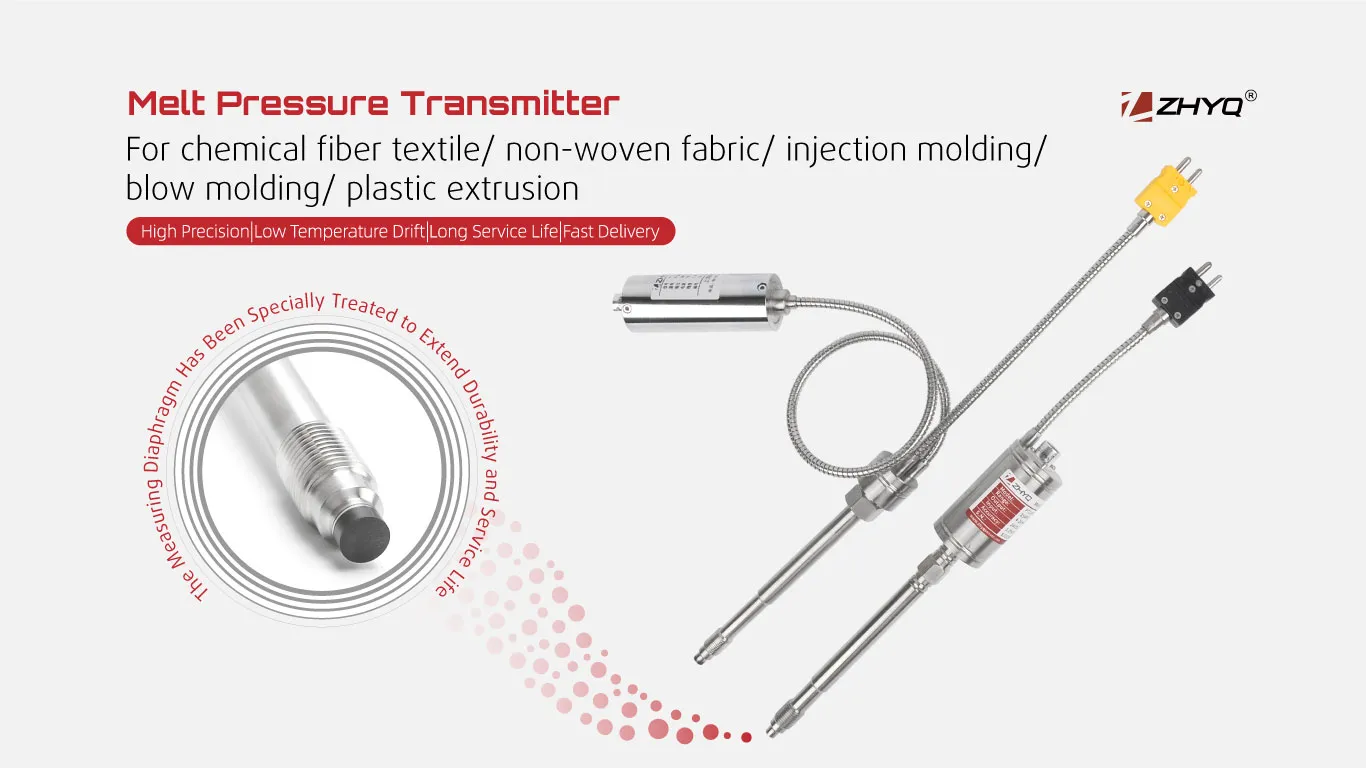

Today, let us take a look at this “smart sentinel” on the production line—the high-temperature melt pressure transmitter, which is redefining the quality benchmark in fiber production. So, what are the unique features and advantages of the high-temperature melt pressure transmitter?

- Melt Spinning

When polymer raw materials undergo high-temperature transformations, subtle differences in melt pressure directly determine the fiber’s denier uniformity and breaking strength. Our transmitters, with a measurement accuracy of ±0.25%, provide precise “vital parameters” for each fiber’s birth.

- Melt Conveying System

In conveying pipelines stretching hundreds of meters, melt pressure transmitters, like sensitive neurons, monitor pressure fluctuations in real time. When the value deviates from the set threshold, the system automatically triggers an alert, preventing a potential “flow interruption crisis” caused by pressure imbalance.

Furthermore, it boasts strong anti-interference capabilities, eliminating various interference factors and providing stable and accurate pressure measurements in complex production environments. Furthermore, its compact design makes it easy to install, saves space, and easily integrates into existing production equipment.

Accurate melt pressure measurement enables production personnel to adjust process parameters promptly, ensuring uniform fiber thickness and strength, and producing high-quality new fiber materials. Such products are more popular in the market and generate higher profits for companies. Furthermore, it improves production efficiency. Stable pressure measurement streamlines the production process, reduces equipment failures and downtime caused by pressure fluctuations, and enables continuous and efficient production line operation.

Accurate pressure data can be combined with automated control systems to achieve precise control of the production process, reducing manual errors and labor intensity. This not only improves a company’s production management capabilities but also significantly reduces labor costs. Furthermore, high-quality products and efficient production can enhance a company’s market competitiveness, establish a positive brand image, and win more opportunities in future market competition.

High-temperature melt pressure transmitters are the “guardians” of the production process for new fiber materials. Add them to your production line now and embark on a new chapter in the production of new fiber materials!