At wastewater treatment plants, pressure transmitters serve as the “sentinels” that ensure the stable operation of influent pumps, filtration units, and sludge pipelines.

To address the three major challenges in wastewater pressure monitoring—media prone to clogging, corrosion, and scaling—the PT124B-214 flush diaphragm pressure transmitter provides an effective solution.

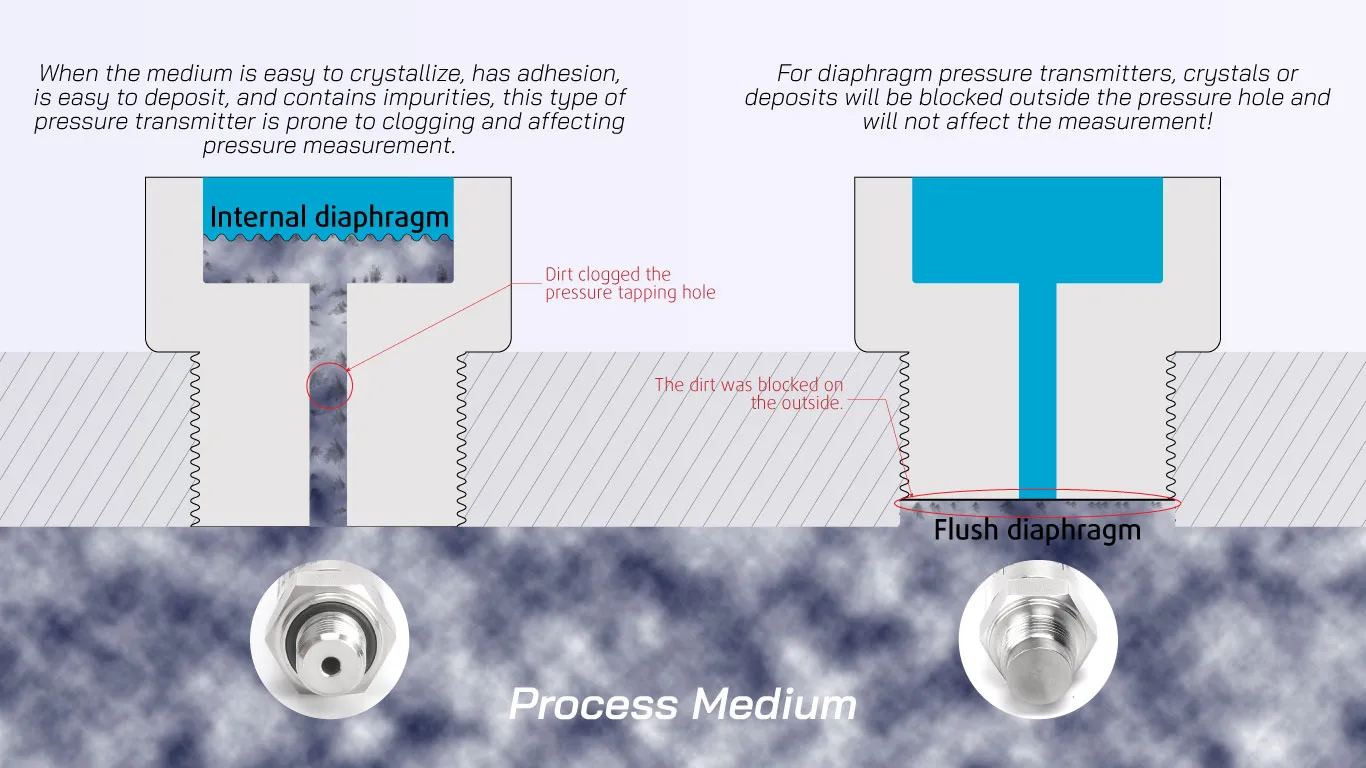

1.No pressure port design with direct media contact: Fibers and sand are flushed away immediately, completely eliminating clogging and signal drift.

2.Hastelloy C276 + PTFE dual-coated diaphragm: Resistant to hydrogen sulfide and strong alkalis, significantly extending the service life of the pressure transmitter. Leak point monitoring is no longer uncertain.

3.Standardized output: Direct integration with PLC or SCADA systems, ensuring accurate, real-time data inclusion in the integrated process control system.

The PT124B-214 flush diaphragm pressure transmitter features a flat-diaphragm sensor at its core, specifically designed for media that are prone to clogging, crystallization, or high viscosity. Its distinctive design includes a cavity-free flat diaphragm that prevents media residue and blockage. Equipped with corrosion- and wear-resistant ceramic or alloy diaphragms, it is well suited for challenging media such as wastewater, sludge, and viscous liquids.

The measurement range covers low- to medium-pressure applications, offering high accuracy and strong stability. With excellent resistance to vibration and shock, it meets the demands of complex industrial environments requiring precise fluid pressure measurement.

With precise real-time measurement and low maintenance costs, it helps wastewater treatment operators reduce downtime risk and improve process stability. Partner with us to make monitoring no longer a “challenge,” but a reliable enabler of efficient operations—lower costs → higher efficiency → enhanced safety assurance.