In the apple juice production line, the detection of sugar content is directly related to the product taste, quality stability and market competitiveness. Many production managers have lamented: “How can we measure the sugar content quickly and accurately?” The traditional detection method always seems to be somewhat unsatisfactory.

- Manual sampling and testing, the process is cumbersome, and the results are often inconsistent;

- Frequent equipment maintenance, the production line is often forced to stop;

- Sugar content control is always lagging, raw materials are wasted, rework is frequent, and cost control pressure is very high…

Traditional juice concentration monitoring: full of hidden dangers

Let’s take a look at the hidden dangers of traditional sugar content testing in the apple juice production process:

- Low efficiency: manual sampling and testing are required every time, and when the test results come out, the apple juice has already flowed into the next link. Problems often occur too late to remedy.

- Human error: Different shifts and different operators, even with the same instrument, may produce very different data, and batch consistency is difficult to ensure.

- Poor real-time performance: sampling can only be performed, and the entire production process cannot be monitored in real time. Often, it is not until the test that the sugar content of a batch exceeds the standard or is low, and the loss is irreversible.

- High operation and maintenance costs: Some chemical methods require frequent replacement of reagents and cleaning of equipment, which are complex to operate and difficult to manage.

These pain points give many production managers a headache. Is there a more worry-free and efficient way?

The inline refractometer uses the principle of light refraction to measure the refractive index of apple juice and calculate the sugar content in real time. Compared with traditional methods, what innovative experience does it bring?

1.Results in one second, truly online real-time detection

The inline refractometer can be directly installed on the pipeline or tank to continuously and automatically monitor the flowing apple juice. No sampling or downtime is required, and real-time data is displayed on the central control screen, so the production status is clear at a glance.

2.Higher precision and stronger stability

The high-quality sensor and algorithm support keep the measurement error within ±0.1°Brix. Even if the quality of raw materials fluctuates and impurities interfere, accurate data can be stably output, truly “speaking with data” and avoiding subjective errors caused by manual judgment.

3.Intelligent linkage, smarter production

After deep integration with the automatic control system, once abnormal sugar content is detected, the system will automatically adjust process parameters such as sugar addition and dilution, and even link alarms and valve closures to prevent unqualified products from entering the market at the first time.

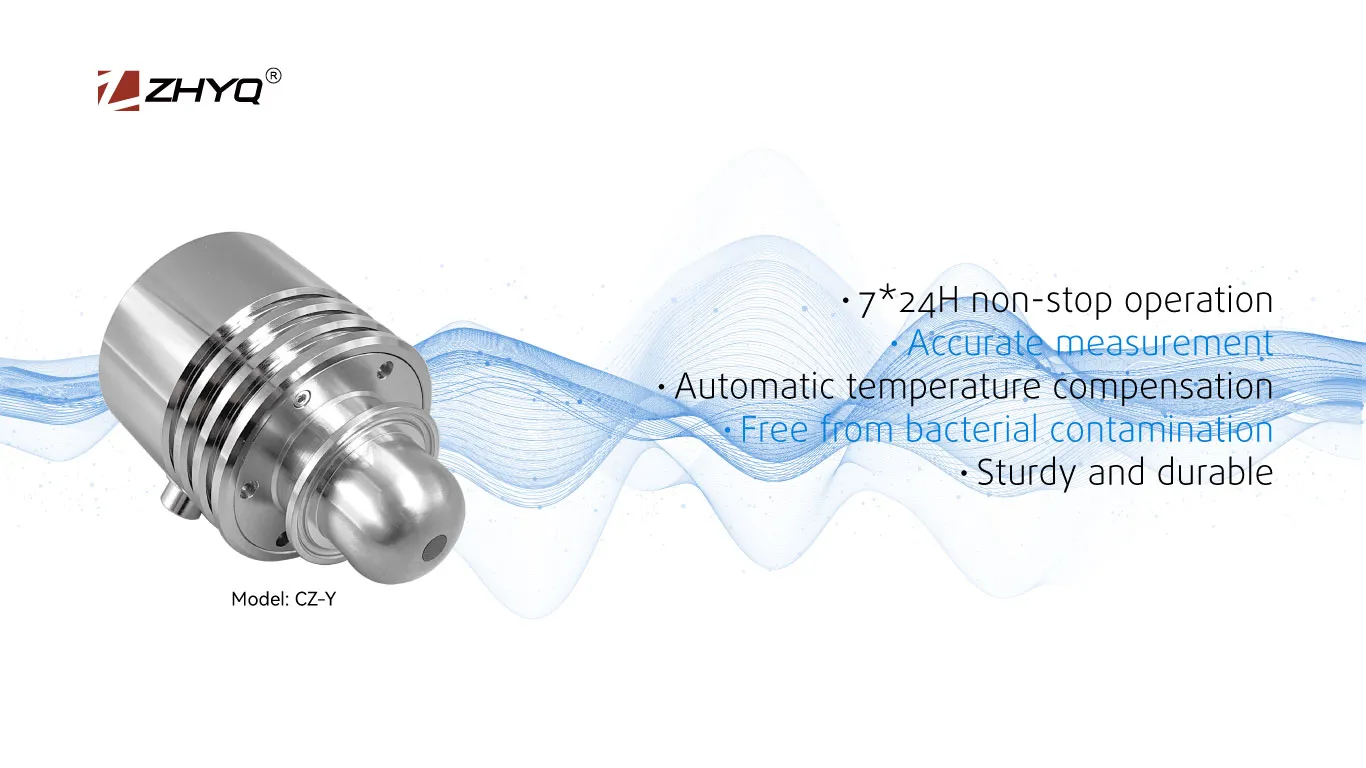

4.Low maintenance, easy to clean

A variety of inline refractometers are equipped with automatic cleaning devices and anti-pollution designs, which greatly reduces the frequency of manual maintenance. The equipment runs stably, helping the production line to achieve all-weather worry-free monitoring.

5.Application scenarios: From mixing to filling, the whole process is covered

In modern apple juice production lines, inline refractometers are usually used in the following links:

- Juice mixing: The sugar content of raw apple juice varies. Inline refractometers can monitor the mixing uniformity in real time to ensure the consistency of the finished product benchmark.

- Filtration and concentration: During the filtration and concentration process, the sugar content changes with the removal of water. Online monitoring helps to accurately control the end point to avoid over-concentration or failure to meet the standard.

- Before filling the finished product: Before the final filling, the sugar content is reviewed in real time to detect abnormal batches in time and ensure the qualified rate of the product leaving the factory.

- Quality traceability: All monitoring data are automatically stored to facilitate subsequent quality analysis and traceability, and realize digital management of the entire process.

As smart manufacturing becomes more and more popular, inline refractometers are becoming the preferred equipment for more and more juice companies. They use technology to make production more efficient, smarter, and more quality-assured. Are you still worried about sugar content testing? Perhaps, you are only one inline refractometer away from high-quality production.