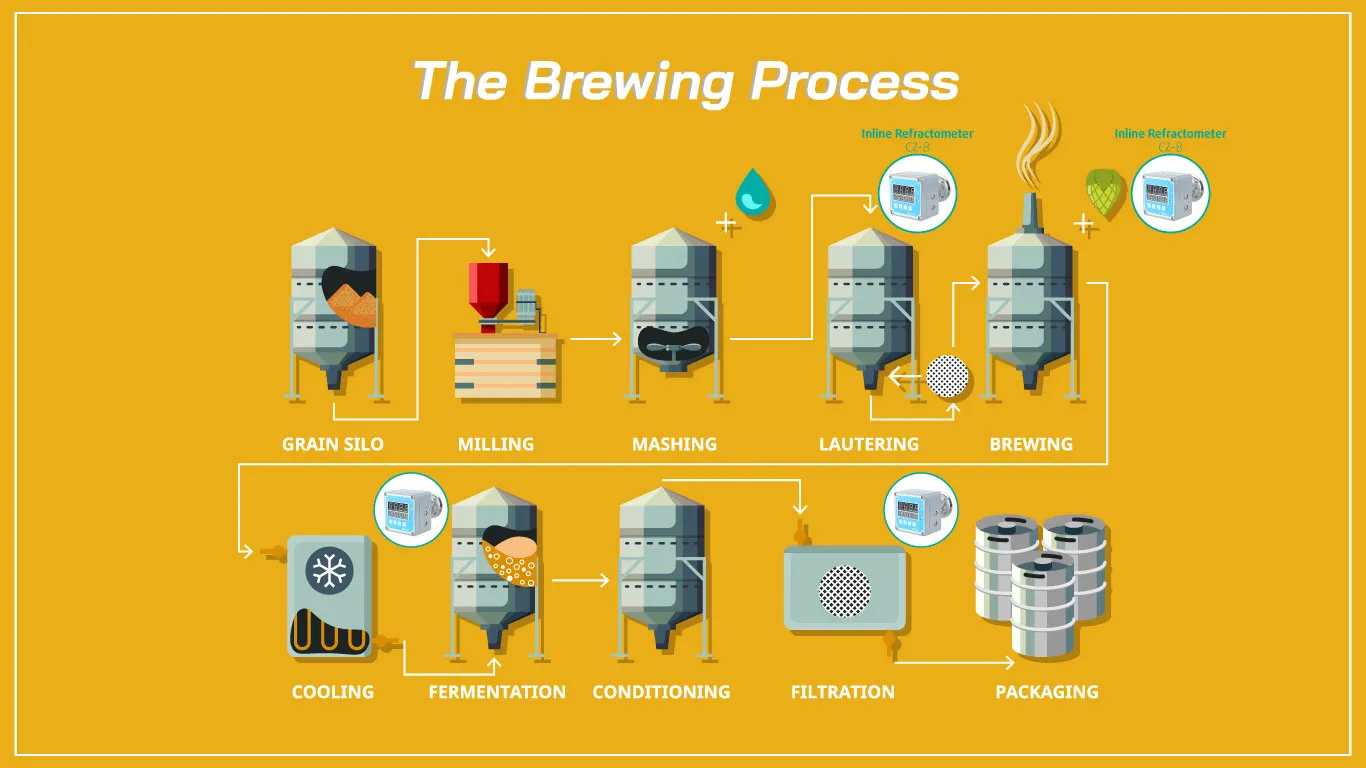

Every summer, a cool beer brings a refreshing, refreshing feeling. But did you know that behind a good beer, besides malt, yeast, and water, the fermentation process, ingredient ratio, and concentration control are equally crucial. The “inline refractometer” is precisely the tool that makes brewing more intelligent and efficient.

Traditional Testing: Slow and Difficult to Consistently Test Quality

In many breweries, concentrations in key stages like saccharification and fermentation often rely on manual sampling and laboratory analysis. This is not only inefficient and time-consuming, but also prone to flavor variations between batches due to human error. During peak production, production management faces numerous risks.

The inline refractometer improves both quality and efficiency!

1. Real-time Monitoring and Transparent Data

The inline refractometer mounts directly on pipes or tanks, collecting real-time data on wort, sugar content, and alcohol content as the wort and beer flow through. Quality fluctuations are instantly visible, eliminating the need for testing!

2. Automated Interaction for Precise Process Control

The inline refractometer can be integrated with automated water, wort, and alcohol addition processes. When concentration fluctuates, the system automatically adjusts the ratio, ensuring consistent flavor from batch to batch.

3. Reduced Labor and Waste

No more frequent sampling and testing, saving labor. Precise control improves raw material utilization and significantly reduces rework and waste.

4. Diverse Applications, Safeguarding the Entire Brewing Process

From saccharification and filtration to fermentation and maturation, every process relies on concentration monitoring. The inline refractometer makes brewery production data visible, traceable, and controllable, truly embodying the spirit of craftsmanship.

If you are still worried about the quality fluctuation and production efficiency during beer production, perhaps an inline refractometer is all you need.