Introduction: In the intelligent system of coal mines, pressure measurement is the cornerstone of safety. ZHYQ’s carefully developed and produced mining intrinsically safe pressure transmitters, with excellent accuracy and ultimate reliability, accurately sense the pressure changes in the mine, build an indestructible safety line for your hydraulic support system, and help the intelligent mine to move forward steadily.

Pressure is the lifeblood of underground coal mine hydraulic support systems. Any abnormal fluctuation in pressure, including the hydraulic support’s support force, the output pressure of the emulsion pump station, and the water pressure, can indicate equipment failure or even the risk of a safety incident.

Say goodbye to traditional pressure monitoring methods with slow response and insufficient accuracy! ZHYQ has launched a series of intrinsically safe pressure transmitters for mining. Leveraging its core technology, these transmitters have become the “smart sentinels” of underground pressure monitoring.

Features 1: Superior Measurement Accuracy

- Precise Measurement: Utilizing a high-performance pressure sensor and advanced signal processing technology, this device achieves high-precision, low-drift pressure measurement. Whether it’s the high pressure of a hydraulic support or subtle changes in pipeline pressure, it can be clearly and accurately captured and converted into a stable signal.

- Fast Response: Its rapid response provides real-time feedback on system pressure changes, providing timely and reliable data to the electro-hydraulic control system (SAC), ensuring precise and timely control.

Feature 2: Intrinsically Safe and Explosion-Proof Design

Safety is a core design concept embedded in our products. This product strictly adheres to national mining safety standards, holds the Mining Product Safety Mark Certificate (MA), and utilizes an intrinsically safe circuit design.

- Absolute Safety: Even in the most hazardous gas and coal dust explosion environments underground, the energy generated by its internal circuitry is strictly limited to safe levels, fundamentally eliminating ignition sources and ensuring the absolute safety of personnel, equipment, and the environment.

- All-Area Adaptability: The wide input voltage design effectively resists fluctuations in the underground power grid and complex electromagnetic interference, ensuring stable and continuous data acquisition.

Features 3: Suitable for Harsh Working Environments

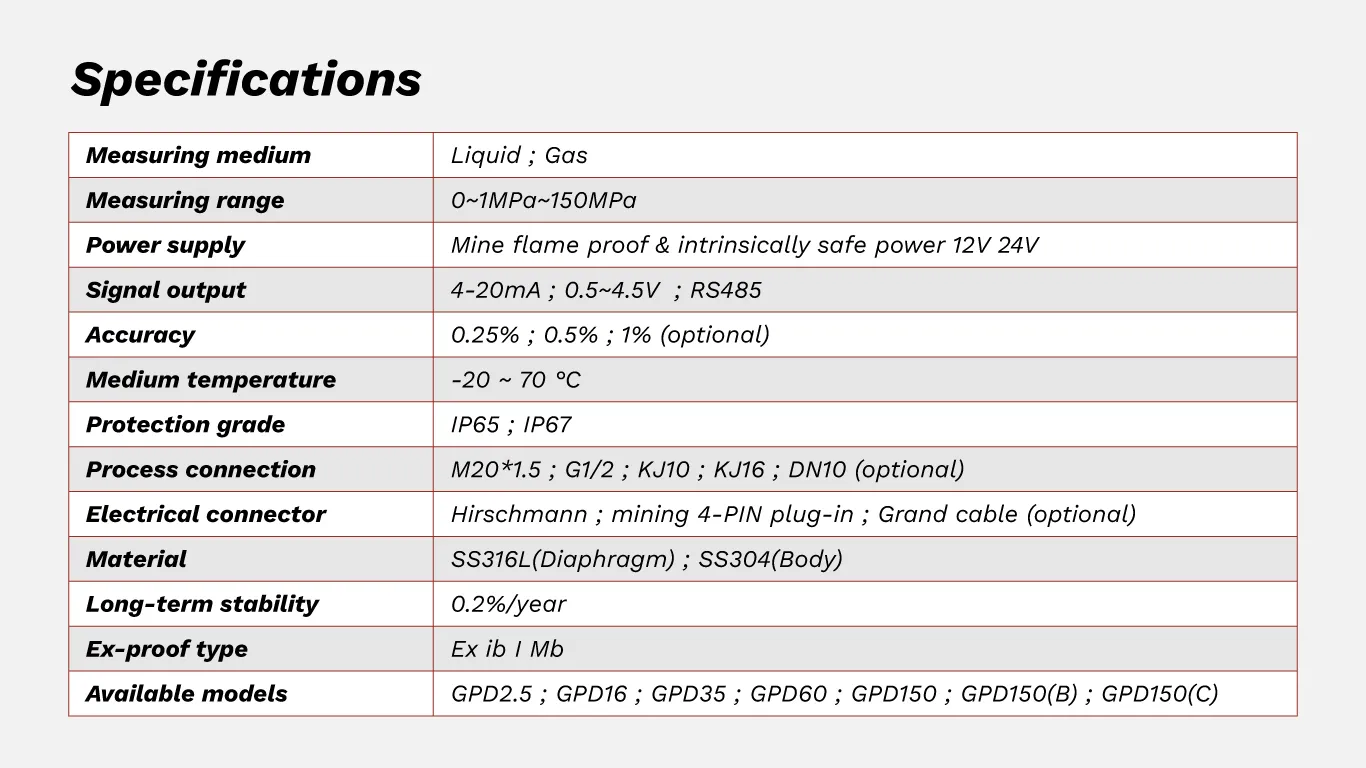

- Rugged and Durable: The housing is made of high-quality stainless steel or high-strength alloy with a special surface treatment for corrosion and impact resistance. With a high IP65/IP67 protection rating, it fully resists underground dust, moisture, and water, and its service life far exceeds that of ordinary products.

- Easy Installation: The compact and lightweight structure offers a variety of process connection interfaces (such as G1/4 and M20*1.5), allowing for easy integration into various pressure measurement points, including pump stations, pipelines, and valve blocks, significantly reducing the difficulty and time required for installation and maintenance.

Typical Applications

- Hydraulic support electro-hydraulic control system: Real-time monitoring of column pressure ensures constant support resistance and closed-loop pressure control, which is key to ensuring roof safety.

- Emulsion pump station and spray pump station: Real-time monitoring of pump station output pressure ensures the stability of the fluid supply system and implements intelligent unloading and energy-saving control.

- Underground water supply and drainage, and compressed air system: Monitoring pipeline pressure ensures the normal operation of the mine’s water supply and compressed air systems.

- Equipment health diagnosis: Pressure waveform analysis provides data support for preventive maintenance of pumps, valves, and other components.